Page 43 - Mechanical Engineer's Data Handbook

P. 43

32 MECHANICAL ENGINEER’S DATA HANDBOOK

rn where: &=frequency for beam only, f,, f2, . . ., are

a b frequencies for each mass.

I

m2

3 rn3

m1

---

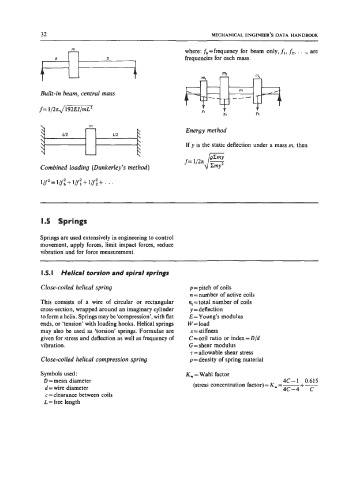

Built-in beam, central mass rn

f= 1/2nJEEi7iZ

Yl

Y2 Y3

Energy method

If y is the static deflection under a mass m, then

Combined loading (Dunkerley’s method)

l/y= + 1fl: + 11: + . . .

1/f:

1.5 Springs

Springs are used extensively in engineering to control

movement, apply forces, limit impact forces, reduce

vibration and for force measurement.

I .5. I Helical torsion and spiral springs

Close-coiled helical spring p=pitch of coils

n = number of active coils

This consists of a wire of circular or rectangular n,=total number of coils

cross-section, wrapped around an imaginary cylinder y = deflection

to form a helix. Springs may be ‘compression’, with flat E =Young’s modulus

ends, or ‘tension’ with loading hooks. Helical springs W=load

may also be used as ‘torsion’ springs. Formulae are s =stiffness

given for stress and deflection as well as frequency of C = coil ratio or index = D/d

vibration. G = shear modulus

7 =allowable shear stress

Close-coiled helical compression spring p =density of spring material

Symbols used: K, = Wahl factor

D = mean diameter 4C-1 0.615

+

4c-4 c

d = wire diameter (stress concentration factor) = K, = - -

c = clearance between coils

L = free length