Page 46 - Mechanical Engineer's Data Handbook

P. 46

STRENGTHS OF MATERIALS 35

I .5.2 Leaf and laminated leaf springs

Leaf springs

A leaf spring consists basically of a beam, usually of flat

strip, e.g. a cantilever or simply supported beam, Quarter-elliptic spring:

subjected to a load to give a desired deflection Maximum bending stress om= 6 WLfnbt’

proportional to the load. Stiffness s = Enbt3/6L3

The laminated leaf spring, or ‘camage spring’, is

used for vehicle suspensions and is made up of several

flat strips of steel of various lengths clamped together.

The spring is effectively a diamond-shaped plate cut

into strips. Analysis shows that the maximum bending

stress is constant.

The quarter-elliptic spring is, in effect, half of the

so-called ’semi-elliptic’ spring.

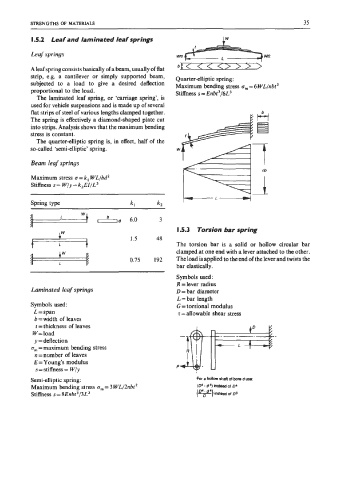

Beam leaf springs

Maximum stress u=k, WLfbd’

Stiffness s= Wfy=k2EIfL3

Spring type kl k2

id+ b 6.0 3

-d

I .5.3 Torsion bar spring

1.5 48

The torsion bar is a solid or hollow circular bar

clamped at one end with a lever attached to the other.

0.75 192 The load is applied to the end of the lever and twists the

bar elastically.

Symbols used:

R =lever radius

Laminated leaf springs D = bar diameter

L = bar length

Symbols used: G = torsional modulus

L = span 7 =allowable shear stress

b = width of leaves

t = thickness of leaves

W = load

y = deflection

urn =maximum bending stress

n =number of leaves

E =Young’s modulus

s = stiffness = WJy P

Semi-elliptic spring: For a hollow shafl of bore dum:

Maximum bending stress u, = 3 WL/2nbt2 (D4 - d insteed of 04

of

insteed

Stiffness s = 8Enbt3 J3 L3 (v) 03