Page 44 - Mechanical Engineer's Data Handbook

P. 44

STRENGTHS OF MATERIALS 33

Load W=xzd2/8CK, Vibration of helical spring

Wire diameter d = dmi

Stiffness S= Gd/8nC3 Axial vibration under own mass:

Deflection y= Wls 1

Total number of coils n,=n+ 1.5 (for ground, Frequency of vibration f = -

flattened ends) 2xdCn

Free length L=(n+l)d+nc

Ratio LID = about 2 to 3 for stability

‘Close-coiled‘ length L, = (n + 1 )d

Torsional vibration under end inertia I:

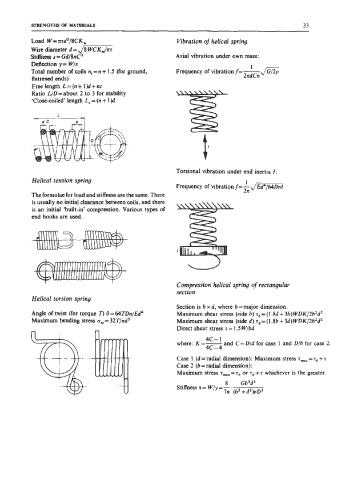

Helical tension spring 1

Frequency of vibration f = z;; d m

The formulae for load and stiffness are the same. There

is usually no initial clearance between coils, and there

is an initial ‘built-in’ compression. Various types of

end hooks are used.

Compression helical spring of rectangular

section

Helical torsion spring

Section is b x d, where b = major dimension.

Angle of twist (for torque r) 8 = 64TDn/Ed4 Maximum shear stress (side b) T*= (1.86 + 36) WDK/2b2dZ

Maximum bending stress 6, = 32T/nd3 Maximum shear stress (side d) T,, = (1.8b + 3d)WDK/2b2d2

Direct shear stress T = 1.5 W/bd

4C-1

where: K =- and C= D/d for case 1 and Dfb for case 2.

4c-4

Case 1 (d = radial dimension): Maximum stress = T~ + T

Case 2 (b = radial dimension):

Maximum stress T,,,,,=T~ or r,+r whichever is the greater.

8 Gb3d3

Stiffness s= W/y=--

7n (b2 +d2)nD3