Page 45 - Mechanical Engineer's Data Handbook

P. 45

34 MECHANICAL ENGINEER’S DATA HANDBOOK

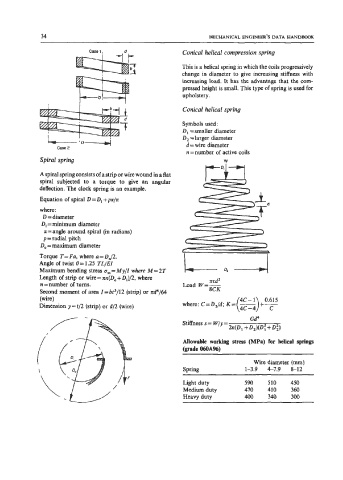

Case 1, .d Conical helical compression spring

This is a helical spring in which the coils progressively

change in diameter to give increasing stiffness with

increasing load. It has the advantage that the com-

pressed height is small. This type of spring is used for

upholstery.

Conical helical spring

Symbols used:

D, =smaller diameter

D, =larger diameter

d = wire diameter

case 2

n = number of active coils

Spiral spring W

A spiral spring consists of a strip or wire wound in a flat

spiral subjected to a torque to give an angular

deflection. The clock spring is an example.

Equation of spiral D = D, + pu/x

where:

D =diameter

Di = minimum diameter

u=angle around spiral (in radians)

p = radial pitch

Do = maximum diameter

Torque T= Fa, where a=DJ2.

Angle of twist 8= 1.25 TL/EI

Maximum bending stress om= My11 where M = 2T

Length of strip or wire = m(D0 + Di)/2, where md2

n = number of turns. Load W=-

Second moment of area I=bt3/12 (strip) or nd4/64 8CK

(wire) 4C-1 0.615

+ c

Dimension y = t/2 (strip) or d/2 (wire) where: C=D,/d; K= -

(4c - 4)

Allowable working stress (MPa) for helical springs

(grade MA%)

Wire diameter (mm)

Spring 1-3.9 4-7.9 8-12

Light duty 590 510 450

Medium duty 470 410 360

Heavy duty 400 340 300