Page 48 - Mechanical Engineer's Data Handbook

P. 48

STRENGTHS OF MATERIALS 37

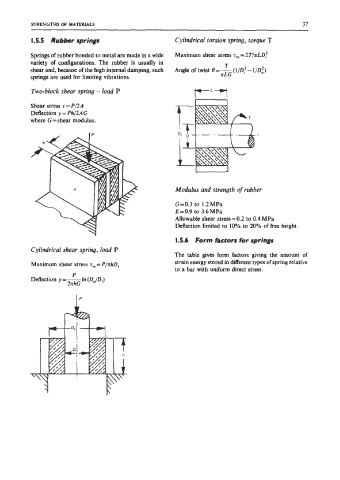

I .5.5 Rubber springs Cylindrical torsion spring, torque T

Springs of rubber bonded to metal are made in a wide Maximum shear stress T,,, = 2T/xLDf

variety of configurations. The rubber is usually in T

shear and, because of the high internal damping, such Angle of twist 0 = - (l/@ - l/D:)

springs are used for limiting vibrations. nLG

Two-block shear spring - load P

Shear stress 7 = P/2A

Deflection y = Ph/SAG

where G =shear modulus.

Modulus and strength of rubber

G=0.3 to 1.2MPa

E =0.9 to 3.6 MPa

Allowable shear stress=0.2 to 0.4 MPa

Deflection limited to 10% to 20% of free height.

1.5.6 Form hcton for springt

Cylindrical shear spring, load P

The table gives form factors giving the amount of

Maximum shear stress T, = P/nhDi strain energy stored in different types of spring relative

to a bar with uniform direct stress.

P

Deflection y = - (DJDi)

In

2nhG