Page 584 - Mechanical Engineers' Handbook (Volume 2)

P. 584

7 Hydraulic Servomotors 575

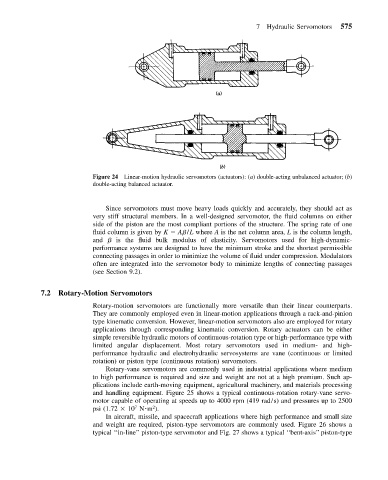

Figure 24 Linear-motion hydraulic servomotors (actuators): (a) double-acting unbalanced actuator; (b)

double-acting balanced actuator.

Since servomotors must move heavy loads quickly and accurately, they should act as

very stiff structural members. In a well-designed servomotor, the fluid columns on either

side of the piston are the most compliant portions of the structure. The spring rate of one

fluid column is given by K A /L where A is the net column area, L is the column length,

and is the fluid bulk modulus of elasticity. Servomotors used for high-dynamic-

performance systems are designed to have the minimum stroke and the shortest permissible

connecting passages in order to minimize the volume of fluid under compression. Modulators

often are integrated into the servomotor body to minimize lengths of connecting passages

(see Section 9.2).

7.2 Rotary-Motion Servomotors

Rotary-motion servomotors are functionally more versatile than their linear counterparts.

They are commonly employed even in linear-motion applications through a rack-and-pinion

type kinematic conversion. However, linear-motion servomotors also are employed for rotary

applications through corresponding kinematic conversion. Rotary actuators can be either

simple reversible hydraulic motors of continuous-rotation type or high-performance type with

limited angular displacement. Most rotary servomotors used in medium- and high-

performance hydraulic and electrohydraulic servosystems are vane (continuous or limited

rotation) or piston type (continuous rotation) servomotors.

Rotary-vane servomotors are commonly used in industrial applications where medium

to high performance is required and size and weight are not at a high premium. Such ap-

plications include earth-moving equipment, agricultural machinery, and materials processing

and handling equipment. Figure 25 shows a typical continuous-rotation rotary-vane servo-

motor capable of operating at speeds up to 4000 rpm (419 rad/s) and pressures up to 2500

7

psi (1.72 10 N m ).

2

In aircraft, missile, and spacecraft applications where high performance and small size

and weight are required, piston-type servomotors are commonly used. Figure 26 shows a

typical ‘‘in-line’’ piston-type servomotor and Fig. 27 shows a typical ‘‘bent-axis’’ piston-type