Page 583 - Mechanical Engineers' Handbook (Volume 2)

P. 583

574 Servoactuators for Closed-Loop Control

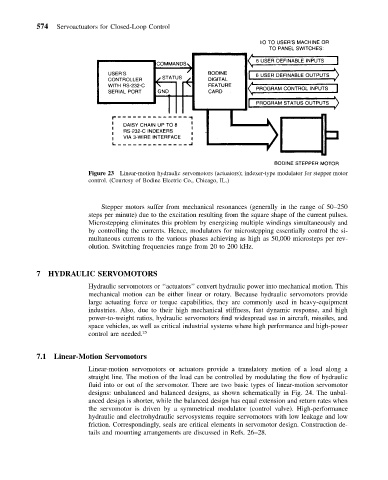

Figure 23 Linear-motion hydraulic servomotors (actuators); indexer-type modulator for stepper motor

control. (Courtesy of Bodine Electric Co., Chicago, IL.)

Stepper motors suffer from mechanical resonances (generally in the range of 50–250

steps per minute) due to the excitation resulting from the square shape of the current pulses.

Microstepping eliminates this problem by energizing multiple windings simultaneously and

by controlling the currents. Hence, modulators for microstepping essentially control the si-

multaneous currents to the various phases achieving as high as 50,000 microsteps per rev-

olution. Switching frequencies range from 20 to 200 kHz.

7 HYDRAULIC SERVOMOTORS

Hydraulic servomotors or ‘‘actuators’’ convert hydraulic power into mechanical motion. This

mechanical motion can be either linear or rotary. Because hydraulic servomotors provide

large actuating force or torque capabilities, they are commonly used in heavy-equipment

industries. Also, due to their high mechanical stiffness, fast dynamic response, and high

power-to-weight ratios, hydraulic servomotors find widespread use in aircraft, missiles, and

space vehicles, as well as critical industrial systems where high performance and high-power

control are needed. 25

7.1 Linear-Motion Servomotors

Linear-motion servomotors or actuators provide a translatory motion of a load along a

straight line. The motion of the load can be controlled by modulating the flow of hydraulic

fluid into or out of the servomotor. There are two basic types of linear-motion servomotor

designs: unbalanced and balanced designs, as shown schematically in Fig. 24. The unbal-

anced design is shorter, while the balanced design has equal extension and return rates when

the servomotor is driven by a symmetrical modulator (control valve). High-performance

hydraulic and electrohydraulic servosystems require servomotors with low leakage and low

friction. Correspondingly, seals are critical elements in servomotor design. Construction de-

tails and mounting arrangements are discussed in Refs. 26–28.