Page 721 - Mechanical Engineers' Handbook (Volume 2)

P. 721

712 General-Purpose Control Devices

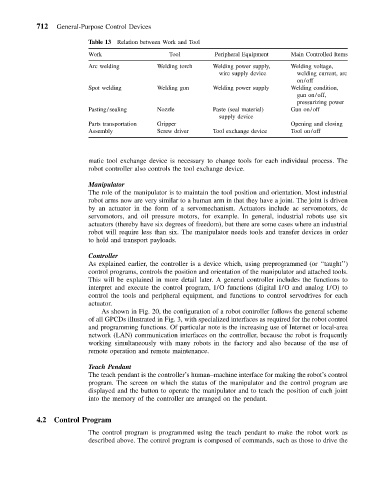

Table 13 Relation between Work and Tool

Work Tool Peripheral Equipment Main Controlled Items

Arc welding Welding torch Welding power supply, Welding voltage,

wire supply device welding current, arc

on/off

Spot welding Welding gun Welding power supply Welding condition,

gun on/off,

pressurizing power

Pasting/sealing Nozzle Paste (seal material) Gun on/off

supply device

Parts transportation Gripper Opening and closing

Assembly Screw driver Tool exchange device Tool on/off

matic tool exchange device is necessary to change tools for each individual process. The

robot controller also controls the tool exchange device.

Manipulator

The role of the manipulator is to maintain the tool position and orientation. Most industrial

robot arms now are very similar to a human arm in that they have a joint. The joint is driven

by an actuator in the form of a servomechanism. Actuators include ac servomotors, dc

servomotors, and oil pressure motors, for example. In general, industrial robots use six

actuators (thereby have six degrees of freedom), but there are some cases where an industrial

robot will require less than six. The manipulator needs tools and transfer devices in order

to hold and transport payloads.

Controller

As explained earlier, the controller is a device which, using preprogrammed (or ‘‘taught’’)

control programs, controls the position and orientation of the manipulator and attached tools.

This will be explained in more detail later. A general controller includes the functions to

interpret and execute the control program, I/O functions (digital I/O and analog I/O) to

control the tools and peripheral equipment, and functions to control servodrives for each

actuator.

As shown in Fig. 20, the configuration of a robot controller follows the general scheme

of all GPCDs illustrated in Fig. 3, with specialized interfaces as required for the robot control

and programming functions. Of particular note is the increasing use of Internet or local-area

network (LAN) communication interfaces on the controller, because the robot is frequently

working simultaneously with many robots in the factory and also because of the use of

remote operation and remote maintenance.

Teach Pendant

The teach pendant is the controller’s human–machine interface for making the robot’s control

program. The screen on which the status of the manipulator and the control program are

displayed and the button to operate the manipulator and to teach the position of each joint

into the memory of the controller are arranged on the pendant.

4.2 Control Program

The control program is programmed using the teach pendant to make the robot work as

described above. The control program is composed of commands, such as those to drive the