Page 722 - Mechanical Engineers' Handbook (Volume 2)

P. 722

4 Robot Controllers 713

Main CPU unit

Compact PCI bus

Main CPU board

Optional

Personal computer

Human board

interface

Teach pendant

Sensor

I/O Motion Ethernet

Control Control

Etc.

Servoamplifier Manipulator

I/O unit

Servoamplifier Auxiliary axis

Operation Field bus

Option:

panel interface

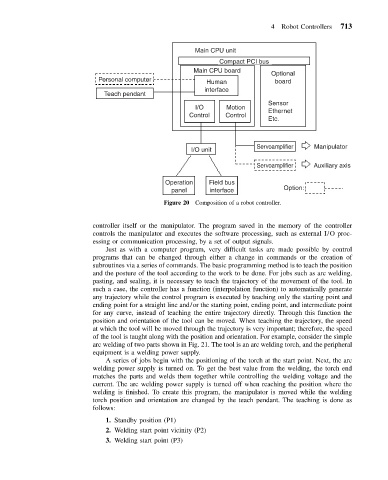

Figure 20 Composition of a robot controller.

controller itself or the manipulator. The program saved in the memory of the controller

controls the manipulator and executes the software processing, such as external I/O proc-

essing or communication processing, by a set of output signals.

Just as with a computer program, very difficult tasks are made possible by control

programs that can be changed through either a change in commands or the creation of

subroutines via a series of commands. The basic programming method is to teach the position

and the posture of the tool according to the work to be done. For jobs such as arc welding,

pasting, and sealing, it is necessary to teach the trajectory of the movement of the tool. In

such a case, the controller has a function (interpolation function) to automatically generate

any trajectory while the control program is executed by teaching only the starting point and

ending point for a straight line and/or the starting point, ending point, and intermediate point

for any curve, instead of teaching the entire trajectory directly. Through this function the

position and orientation of the tool can be moved. When teaching the trajectory, the speed

at which the tool will be moved through the trajectory is very important; therefore, the speed

of the tool is taught along with the position and orientation. For example, consider the simple

arc welding of two parts shown in Fig. 21. The tool is an arc welding torch, and the peripheral

equipment is a welding power supply.

A series of jobs begin with the positioning of the torch at the start point. Next, the arc

welding power supply is turned on. To get the best value from the welding, the torch end

matches the parts and welds them together while controlling the welding voltage and the

current. The arc welding power supply is turned off when reaching the position where the

welding is finished. To create this program, the manipulator is moved while the welding

torch position and orientation are changed by the teach pendant. The teaching is done as

follows:

1. Standby position (P1)

2. Welding start point vicinity (P2)

3. Welding start point (P3)