Page 723 - Mechanical Engineers' Handbook (Volume 2)

P. 723

714 General-Purpose Control Devices

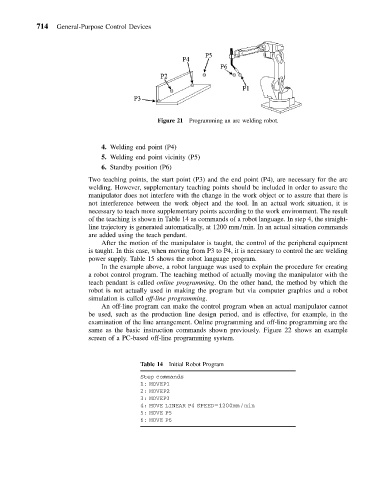

Figure 21 Programming an arc welding robot.

4. Welding end point (P4)

5. Welding end point vicinity (P5)

6. Standby position (P6)

Two teaching points, the start point (P3) and the end point (P4), are necessary for the arc

welding. However, supplementary teaching points should be included in order to assure the

manipulator does not interfere with the change in the work object or to assure that there is

not interference between the work object and the tool. In an actual work situation, it is

necessary to teach more supplementary points according to the work environment. The result

of the teaching is shown in Table 14 as commands of a robot language. In step 4, the straight-

line trajectory is generated automatically, at 1200 mm/min. In an actual situation commands

are added using the teach pendant.

After the motion of the manipulator is taught, the control of the peripheral equipment

is taught. In this case, when moving from P3 to P4, it is necessary to control the arc welding

power supply. Table 15 shows the robot language program.

In the example above, a robot language was used to explain the procedure for creating

a robot control program. The teaching method of actually moving the manipulator with the

teach pendant is called online programming. On the other hand, the method by which the

robot is not actually used in making the program but via computer graphics and a robot

simulation is called off-line programming.

An off-line program can make the control program when an actual manipulator cannot

be used, such as the production line design period, and is effective, for example, in the

examination of the line arrangement. Online programming and off-line programming are the

same as the basic instruction commands shown previously. Figure 22 shows an example

screen of a PC-based off-line programming system.

Table 14 Initial Robot Program

Step commands

1: MOVEP1

2: MOVEP2

3: MOVEP3

4: MOVE LINEAR P4 SPEED 1200mm/min

5: MOVE P5

6: MOVE P6