Page 214 - Mechanical Engineers' Handbook (Volume 4)

P. 214

4 Boiling and Condensation Heat Transfer 203

Film Condensation Inside Horizontal Tubes

For low vapor velocities such that Re based on the vapor velocities at the pipe inlet is less

D

than 3500 24

Nu 0.555 g ( )h D 3 0.25

fg

l

l

l

D

k (T sat T )

ll

s

25

where h ⁄8C (T sat T ) . For higher flow rate, Re 5 l0 ,

4

3

s

p,l

G

fg

0.8 1 / 3

D

Nu 0.0265 Re G Pr

where the Reynolds number Re GD/ is based on the equivalent mass velocity G G l

l

G

G ( / ) . The mass velocity for the liquid G and that for vapor G are calculated as

0.5

v

l

v

v

l

if each occupied the entire flow area.

The Effect of Noncondensable Gases

If noncondensable gas such as air is present in a vapor, even in a small amount, the heat-

transfer coefficient for condensation may be greatly reduced. It has been found that the

presence of a few percent of air by volume in steam reduces the coefficient by 50% or more.

Therefore, it is desirable in the condenser design to vent the noncondensable gases as much

as possible.

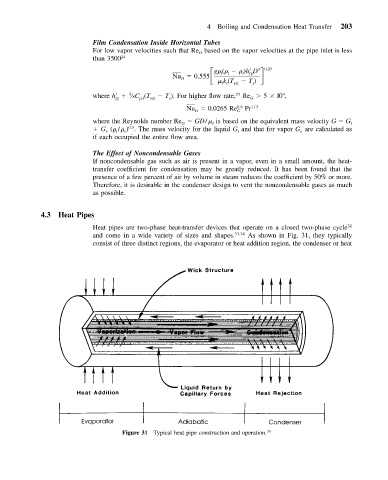

4.3 Heat Pipes

Heat pipes are two-phase heat-transfer devices that operate on a closed two-phase cycle 32

and come in a wide variety of sizes and shapes. 33,34 As shown in Fig. 31, they typically

consist of three distinct regions, the evaporator or heat addition region, the condenser or heat

Figure 31 Typical heat pipe construction and operation. 35