Page 306 - Mechanical Engineers' Handbook (Volume 4)

P. 306

Mechanical Engineers’ Handbook: Energy and Power, Volume 4, Third Edition.

Edited by Myer Kutz

Copyright 2006 by John Wiley & Sons, Inc.

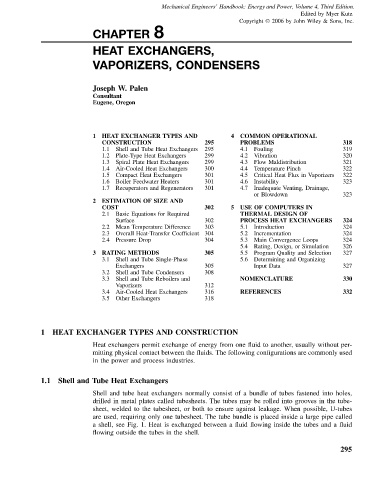

CHAPTER 8

HEAT EXCHANGERS,

VAPORIZERS, CONDENSERS

Joseph W. Palen

Consultant

Eugene, Oregon

1 HEAT EXCHANGER TYPES AND 4 COMMON OPERATIONAL

CONSTRUCTION 295 PROBLEMS 318

1.1 Shell and Tube Heat Exchangers 295 4.1 Fouling 319

1.2 Plate-Type Heat Exchangers 299 4.2 Vibration 320

1.3 Spiral Plate Heat Exchangers 299 4.3 Flow Maldistribution 321

1.4 Air-Cooled Heat Exchangers 300 4.4 Temperature Pinch 322

1.5 Compact Heat Exchangers 301 4.5 Critical Heat Flux in Vaporizers 322

1.6 Boiler Feedwater Heaters 301 4.6 Instability 323

1.7 Recuperators and Regenerators 301 4.7 Inadequate Venting, Drainage,

or Blowdown 323

2 ESTIMATION OF SIZE AND

COST 302 5 USE OF COMPUTERS IN

2.1 Basic Equations for Required THERMAL DESIGN OF

Surface 302 PROCESS HEAT EXCHANGERS 324

2.2 Mean Temperature Difference 303 5.1 Introduction 324

2.3 Overall Heat-Transfer Coefficient 304 5.2 Incrementation 324

2.4 Pressure Drop 304 5.3 Main Convergence Loops 324

5.4 Rating, Design, or Simulation 326

3 RATING METHODS 305 5.5 Program Quality and Selection 327

3.1 Shell and Tube Single-Phase 5.6 Determining and Organizing

Exchangers 305 Input Data 327

3.2 Shell and Tube Condensers 308

3.3 Shell and Tube Reboilers and NOMENCLATURE 330

Vaporizers 312

3.4 Air-Cooled Heat Exchangers 316 REFERENCES 332

3.5 Other Exchangers 318

1 HEAT EXCHANGER TYPES AND CONSTRUCTION

Heat exchangers permit exchange of energy from one fluid to another, usually without per-

mitting physical contact between the fluids. The following configurations are commonly used

in the power and process industries.

1.1 Shell and Tube Heat Exchangers

Shell and tube heat exchangers normally consist of a bundle of tubes fastened into holes,

drilled in metal plates called tubesheets. The tubes may be rolled into grooves in the tube-

sheet, welded to the tubesheet, or both to ensure against leakage. When possible, U-tubes

are used, requiring only one tubesheet. The tube bundle is placed inside a large pipe called

a shell, see Fig. 1. Heat is exchanged between a fluid flowing inside the tubes and a fluid

flowing outside the tubes in the shell.

295