Page 308 - Mechanical Engineers' Handbook (Volume 4)

P. 308

1 Heat Exchanger Types and Construction 297

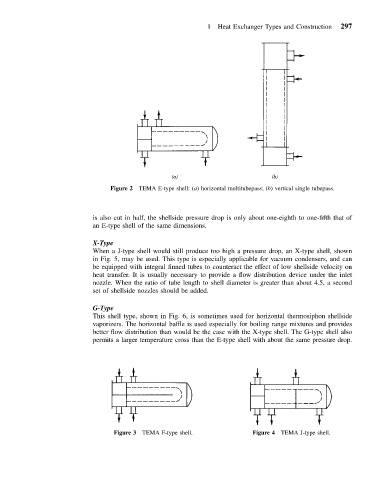

Figure 2 TEMA E-type shell: (a) horizontal multitubepass; (b) vertical single tubepass.

is also cut in half, the shellside pressure drop is only about one-eighth to one-fifth that of

an E-type shell of the same dimensions.

X-Type

When a J-type shell would still produce too high a pressure drop, an X-type shell, shown

in Fig. 5, may be used. This type is especially applicable for vacuum condensers, and can

be equipped with integral finned tubes to counteract the effect of low shellside velocity on

heat transfer. It is usually necessary to provide a flow distribution device under the inlet

nozzle. When the ratio of tube length to shell diameter is greater than about 4.5, a second

set of shellside nozzles should be added.

G-Type

This shell type, shown in Fig. 6, is sometimes used for horizontal thermosiphon shellside

vaporizers. The horizontal baffle is used especially for boiling range mixtures and provides

better flow distribution than would be the case with the X-type shell. The G-type shell also

permits a larger temperature cross than the E-type shell with about the same pressure drop.

Figure 3 TEMA F-type shell. Figure 4 TEMA J-type shell.