Page 312 - Mechanical Engineers' Handbook (Volume 4)

P. 312

1 Heat Exchanger Types and Construction 301

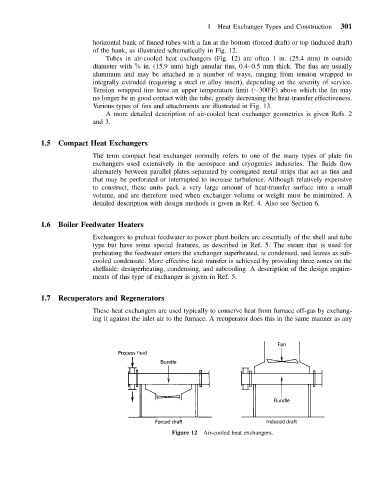

horizontal bank of finned tubes with a fan at the bottom (forced draft) or top (induced draft)

of the bank, as illustrated schematically in Fig. 12.

Tubes in air-cooled heat exchangers (Fig. 12) are often 1 in. (25.4 mm) in outside

diameter with ⁄8 in. (15.9 mm) high annular fins, 0.4–0.5 mm thick. The fins are usually

5

aluminum and may be attached in a number of ways, ranging from tension wrapped to

integrally extruded (requiring a steel or alloy insert), depending on the severity of service.

Tension wrapped fins have an upper temperature limit ( 300 F) above which the fin may

no longer be in good contact with the tube, greatly decreasing the heat-transfer effectiveness.

Various types of fins and attachments are illustrated in Fig. 13.

A more detailed description of air-cooled heat exchanger geometries is given Refs. 2

and 3.

1.5 Compact Heat Exchangers

The term compact heat exchanger normally refers to one of the many types of plate fin

exchangers used extensively in the aerospace and cryogenics industries. The fluids flow

alternately between parallel plates separated by corrugated metal strips that act as fins and

that may be perforated or interrupted to increase turbulence. Although relatively expensive

to construct, these units pack a very large amount of heat-transfer surface into a small

volume, and are therefore used when exchanger volume or weight must be minimized. A

detailed description with design methods is given in Ref. 4. Also see Section 6.

1.6 Boiler Feedwater Heaters

Exchangers to preheat feedwater to power plant boilers are essentially of the shell and tube

type but have some special features, as described in Ref. 5. The steam that is used for

preheating the feedwater enters the exchanger superheated, is condensed, and leaves as sub-

cooled condensate. More effective heat transfer is achieved by providing three zones on the

shellside: desuperheating, condensing, and subcooling. A description of the design require-

ments of this type of exchanger is given in Ref. 5.

1.7 Recuperators and Regenerators

These heat exchangers are used typically to conserve heat from furnace off-gas by exchang-

ing it against the inlet air to the furnace. A recuperator does this in the same manner as any

Figure 12 Air-cooled heat exchangers.