Page 362 - Mechanical Engineers' Handbook (Volume 4)

P. 362

4 Heat-Pipe Fabrication Processes 351

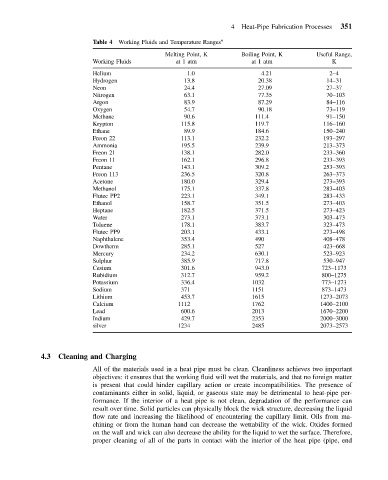

Table 4 Working Fluids and Temperature Ranges 9

Melting Point, K Boiling Point, K Useful Range,

Working Fluids at 1 atm at 1 atm K

Helium 1.0 4.21 2–4

Hydrogen 13.8 20.38 14–31

Neon 24.4 27.09 27–37

Nitrogen 63.1 77.35 70–103

Argon 83.9 87.29 84–116

Oxygen 54.7 90.18 73–119

Methane 90.6 111.4 91–150

Krypton 115.8 119.7 116–160

Ethane 89.9 184.6 150–240

Freon 22 113.1 232.2 193–297

Ammonia 195.5 239.9 213–373

Freon 21 138.1 282.0 233–360

Freon 11 162.1 296.8 233–393

Pentane 143.1 309.2 253–393

Freon 113 236.5 320.8 263–373

Acetone 180.0 329.4 273–393

Methanol 175.1 337.8 283–403

Flutec PP2 223.1 349.1 283–433

Ethanol 158.7 351.5 273–403

Heptane 182.5 371.5 273–423

Water 273.1 373.1 303–473

Toluene 178.1 383.7 323–473

Flutec PP9 203.1 433.1 273–498

Naphthalene 353.4 490 408–478

Dowtherm 285.1 527 423–668

Mercury 234.2 630.1 523–923

Sulphur 385.9 717.8 530–947

Cesium 301.6 943.0 723–1173

Rubidium 312.7 959.2 800–1275

Potassium 336.4 1032 773–1273

Sodium 371 1151 873–1473

Lithium 453.7 1615 1273–2073

Calcium 1112 1762 1400–2100

Lead 600.6 2013 1670–2200

Indium 429.7 2353 2000–3000

silver 1234 2485 2073–2573

4.3 Cleaning and Charging

All of the materials used in a heat pipe must be clean. Cleanliness achieves two important

objectives: it ensures that the working fluid will wet the materials, and that no foreign matter

is present that could hinder capillary action or create incompatibilities. The presence of

contaminants either in solid, liquid, or gaseous state may be detrimental to heat-pipe per-

formance. If the interior of a heat pipe is not clean, degradation of the performance can

result over time. Solid particles can physically block the wick structure, decreasing the liquid

flow rate and increasing the likelihood of encountering the capillary limit. Oils from ma-

chining or from the human hand can decrease the wettability of the wick. Oxides formed

on the wall and wick can also decrease the ability for the liquid to wet the surface. Therefore,

proper cleaning of all of the parts in contact with the interior of the heat pipe (pipe, end