Page 494 - Mechanical Engineers' Handbook (Volume 4)

P. 494

3 Cryogenic Heat-Transfer Methods 483

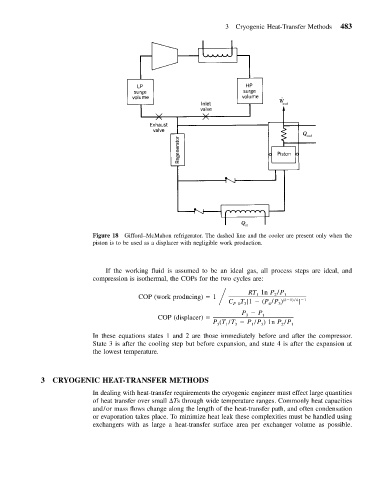

Figure 18 Gifford–McMahon refrigerator. The dashed line and the cooler are present only when the

piston is to be used as a displacer with negligible work production.

If the working fluid is assumed to be an ideal gas, all process steps are ideal, and

compression is isothermal, the COPs for the two cycles are:

COP (work producing) 1 RT 1n P /P 1

2

1

]

T [1 (P /P )

C P 03 4 3 (k 1) / k 1

P P

COP (displacer) 3 1

P (T /T P /P )1n P /P 1

1

3

3

2

1

3

In these equations states 1 and 2 are those immediately before and after the compressor.

State 3 is after the cooling step but before expansion, and state 4 is after the expansion at

the lowest temperature.

3 CRYOGENIC HEAT-TRANSFER METHODS

In dealing with heat-transfer requirements the cryogenic engineer must effect large quantities

of heat transfer over small Ts through wide temperature ranges. Commonly heat capacities

and/or mass flows change along the length of the heat-transfer path, and often condensation

or evaporation takes place. To minimize heat leak these complexities must be handled using

exchangers with as large a heat-transfer surface area per exchanger volume as possible.