Page 307 - Mechanics of Asphalt Microstructure and Micromechanics

P. 307

Applications of Discrete Element Method 299

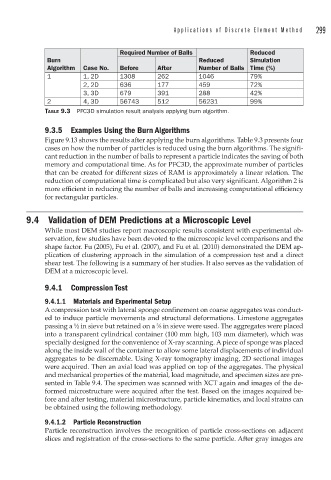

Required Number of Balls Reduced

Burn Reduced Simulation

Algorithm Case No. Before After Number of Balls Time (%)

1 1, 2D 1308 262 1046 79%

2, 2D 636 177 459 72%

3, 3D 679 391 288 42%

2 4, 3D 56743 512 56231 99%

TABLE 9.3 PFC3D simulation result analysis applying burn algorithm.

9.3.5 Examples Using the Burn Algorithms

Figure 9.13 shows the results after applying the burn algorithms. Table 9.3 presents four

cases on how the number of particles is reduced using the burn algorithms. The signifi-

cant reduction in the number of balls to represent a particle indicates the saving of both

memory and computational time. As for PFC3D, the approximate number of particles

that can be created for different sizes of RAM is approximately a linear relation. The

reduction of computational time is complicated but also very significant. Algorithm 2 is

more efficient in reducing the number of balls and increasing computational efficiency

for rectangular particles.

9.4 Validation of DEM Predictions at a Microscopic Level

While most DEM studies report macroscopic results consistent with experimental ob-

servation, few studies have been devoted to the microscopic level comparisons and the

shape factor. Fu (2005), Fu et al. (2007), and Fu et al. (2010) demonstrated the DEM ap-

plication of clustering approach in the simulation of a compression test and a direct

shear test. The following is a summary of her studies. It also serves as the validation of

DEM at a microscopic level.

9.4.1 Compression Test

9.4.1.1 Materials and Experimental Setup

A compression test with lateral sponge confinement on coarse aggregates was conduct-

ed to induce particle movements and structural deformations. Limestone aggregates

3

passing a ½ in sieve but retained on a ⁄8 in sieve were used. The aggregates were placed

into a transparent cylindrical container (100 mm high, 103 mm diameter), which was

specially designed for the convenience of X-ray scanning. A piece of sponge was placed

along the inside wall of the container to allow some lateral displacements of individual

aggregates to be discernable. Using X-ray tomography imaging, 2D sectional images

were acquired. Then an axial load was applied on top of the aggregates. The physical

and mechanical properties of the material, load magnitude, and specimen sizes are pre-

sented in Table 9.4. The specimen was scanned with XCT again and images of the de-

formed microstructure were acquired after the test. Based on the images acquired be-

fore and after testing, material microstructure, particle kinematics, and local strains can

be obtained using the following methodology.

9.4.1.2 Particle Reconstruction

Particle reconstruction involves the recognition of particle cross-sections on adjacent

slices and registration of the cross-sections to the same particle. After gray images are