Page 312 - Mechanics of Asphalt Microstructure and Micromechanics

P. 312

304 Ch a p t e r N i n e

Macro-Strain

No. d x d y d z d xy d yz d xz

1 0.00 –0.05 –0.05 –0.04 0.02 –0.04

2 0.70 –1.10 –0.80 –0.43 –0.08 –0.97

3 0.07 –0.08 0.00 0.10 0.11 0.30

4 –0.14 0.03 3.35 0.15 0.33 –0.42

5 0.17 –0.26 –0.04 0.10 0.05 –0.09

6 0.02 0.12 –0.21 0.05 0.09 –0.05

7 0.01 0.03 –0.09 –0.01 0.05 –0.04

8 0.20 0.07 0.02 0.00 0.14 –0.03

9 –0.04 0.07 0.45 –0.04 0.03 –0.16

10 2.32 –1.03 –0.14 –2.11 –1.19 2.58

TABLE 9.6 Local macro-strains from experimental measurements (in 10 tetrahedrons).

3D

9.4.1.7 PFC and DEM Simulation

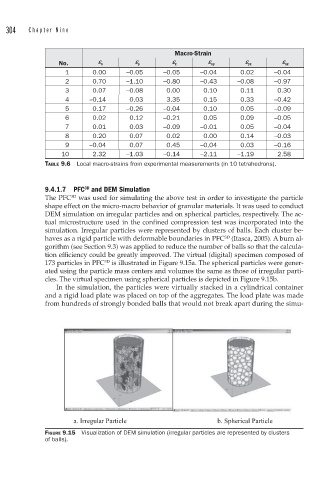

The PFC was used for simulating the above test in order to investigate the particle

3D

shape effect on the micro-macro behavior of granular materials. It was used to conduct

DEM simulation on irregular particles and on spherical particles, respectively. The ac-

tual microstructure used in the confined compression test was incorporated into the

simulation. Irregular particles were represented by clusters of balls. Each cluster be-

3D

haves as a rigid particle with deformable boundaries in PFC (Itasca, 2005). A burn al-

gorithm (see Section 9.3) was applied to reduce the number of balls so that the calcula-

tion efficiency could be greatly improved. The virtual (digital) specimen composed of

173 particles in PFC is illustrated in Figure 9.15a. The spherical particles were gener-

3D

ated using the particle mass centers and volumes the same as those of irregular parti-

cles. The virtual specimen using spherical particles is depicted in Figure 9.15b.

In the simulation, the particles were virtually stacked in a cylindrical container

and a rigid load plate was placed on top of the aggregates. The load plate was made

from hundreds of strongly bonded balls that would not break apart during the simu-

a. Irregular Particle b. Spherical Particle

FIGURE 9.15 Visualization of DEM simulation (irregular particles are represented by clusters

of balls).