Page 247 - Mechanics of Microelectromechanical Systems

P. 247

234 Chapter 4

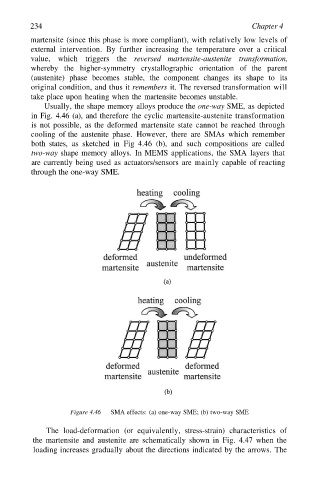

martensite (since this phase is more compliant), with relatively low levels of

external intervention. By further increasing the temperature over a critical

value, which triggers the reversed martensite-austenite transformation,

whereby the higher-symmetry crystallographic orientation of the parent

(austenite) phase becomes stable, the component changes its shape to its

original condition, and thus it remembers it. The reversed transformation will

take place upon heating when the martensite becomes unstable.

Usually, the shape memory alloys produce the one-way SME, as depicted

in Fig. 4.46 (a), and therefore the cyclic martensite-austenite transformation

is not possible, as the deformed martensite state cannot be reached through

cooling of the austenite phase. However, there are SMAs which remember

both states, as sketched in Fig 4.46 (b), and such compositions are called

two-way shape memory alloys. In MEMS applications, the SMA layers that

are currently being used as actuators/sensors are mainly capable of reacting

through the one-way SME.

Figure 4.46 SMA effects: (a) one-way SME; (b) two-way SME

The load-deformation (or equivalently, stress-strain) characteristics of

the martensite and austenite are schematically shown in Fig. 4.47 when the

loading increases gradually about the directions indicated by the arrows. The