Page 249 - Mechanics of Microelectromechanical Systems

P. 249

236 Chapter 4

The other important feature of certain SMAs, the superelasticity

(sometimes called pseudoelasticity), is depicted in Fig. 4.48. Figure 4.48

shows the force-temperature characteristics of four different SMA

compositions, each of them corresponding to a temperature which is relevant

to either the martensitic transformation or the reversed one. The temperatures

denoted by and symbolize the start of the martensitic transformation

and the end (finish) of it, respectively. Similarly, and represent the

same points for the austenite phase. For temperatures smaller than the

entire composition is martensite, whereas for temperatures higher than the

SMA is completely in its austenitic phase, in the absence of loading.

Obviously, for temperatures within the range, the SMA contains both

phases. The SE effect, as suggested in this figure, consists in heating the

SMA over the point (where only the austenite exists in stable condition),

and loading the mechanical component at constant temperature (iso-

thermally) – direction 1 in Fig. 4.48. In doing so, a final state can be reached

where the martensite fraction predominates and where large superelastic

deformations of 15-18% can be achieved easily, since the plateau region

permits it. By downloading the mechanical component, along direction 2 in

the same figure, it is possible to reach the initial state. However, the

generation of the SE effect is more complex and manifests itself as a

spontaneous, stress-free phenomenon, which takes place in certain shape

memory alloys after many cycles of so-called training. Training consists of

combined thermal and mechanical loading which alters the crystallographic

structure of an SMA in order to favor SE behavior – Otsuka and Wayman

[10].

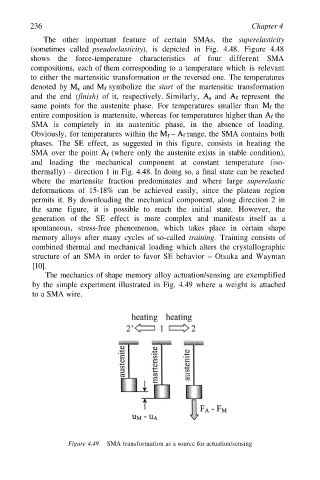

The mechanics of shape memory alloy actuation/sensing are exemplified

by the simple experiment illustrated in Fig. 4.49 where a weight is attached

to a SMA wire.

Figure 4.49 SMA transformation as a source for actuation/sensing