Page 155 - Mechatronic Systems Modelling and Simulation with HDLs

P. 155

144 7 MECHATRONICS

Lambda

Accelerator Idle a NOx value

pedal setting ig

a pe m idle CO value

+

Throttle +

valve m tv HC value

m air a pe

Mixture Gear Kick Kickdown

preparation selection

Lambda Gear

Torque Automatic Wheel Road

generation transmission (rot. -> trans.) gradient

a Torque/ Torque / Force /

m fuel ig rot. vel. rot. vel. velocity Air

Digital n rev friction

controller t

m air rev

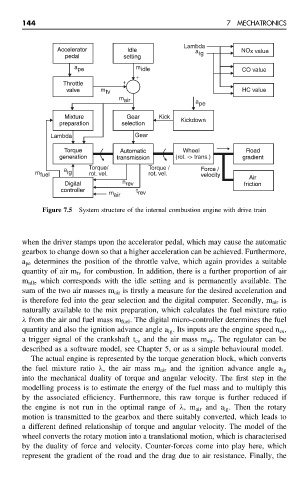

Figure 7.5 System structure of the internal combustion engine with drive train

when the driver stamps upon the accelerator pedal, which may cause the automatic

gearbox to change down so that a higher acceleration can be achieved. Furthermore,

a pe determines the position of the throttle valve, which again provides a suitable

quantity of air m tv for combustion. In addition, there is a further proportion of air

m idle which corresponds with the idle setting and is permanently available. The

sum of the two air masses m air is firstly a measure for the desired acceleration and

is therefore fed into the gear selection and the digital computer. Secondly, m air is

naturally available to the mix preparation, which calculates the fuel mixture ratio

λ from the air and fuel mass m fuel . The digital micro-controller determines the fuel

quantity and also the ignition advance angle a ig . Its inputs are the engine speed n cs ,

a trigger signal of the crankshaft t cs and the air mass m air . The regulator can be

described as a software model, see Chapter 5, or as a simple behavioural model.

The actual engine is represented by the torque generation block, which converts

the fuel mixture ratio λ, the air mass m air and the ignition advance angle a ig

into the mechanical duality of torque and angular velocity. The first step in the

modelling process is to estimate the energy of the fuel mass and to multiply this

by the associated efficiency. Furthermore, this raw torque is further reduced if

the engine is not run in the optimal range of λ,m air and a ig . Then the rotary

motion is transmitted to the gearbox and there suitably converted, which leads to

a different defined relationship of torque and angular velocity. The model of the

wheel converts the rotary motion into a translational motion, which is characterised

by the duality of force and velocity. Counter-forces come into play here, which

represent the gradient of the road and the drag due to air resistance. Finally, the