Page 160 - Mechatronic Systems Modelling and Simulation with HDLs

P. 160

7.4 DEMONSTRATOR 3: CAMERA WINDER 149

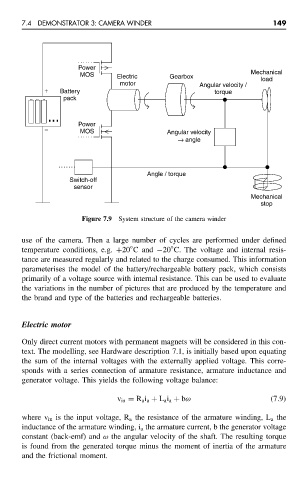

Power

MOS Electric Gearbox Mechanical

load

motor Angular velocity /

+ Battery torque

pack

Power

− MOS Angular velocity

→ angle

Angle / torque

Switch-off

sensor

Mechanical

stop

Figure 7.9 System structure of the camera winder

use of the camera. Then a large number of cycles are performed under defined

◦

◦

temperature conditions, e.g. +20 C and −20 C. The voltage and internal resis-

tance are measured regularly and related to the charge consumed. This information

parameterises the model of the battery/rechargeable battery pack, which consists

primarily of a voltage source with internal resistance. This can be used to evaluate

the variations in the number of pictures that are produced by the temperature and

the brand and type of the batteries and rechargeable batteries.

Electric motor

Only direct current motors with permanent magnets will be considered in this con-

text. The modelling, see Hardware description 7.1, is initially based upon equating

the sum of the internal voltages with the externally applied voltage. This corre-

sponds with a series connection of armature resistance, armature inductance and

generator voltage. This yields the following voltage balance:

v in = R a i a + L a i a + bω (7.9)

where v in is the input voltage, R a the resistance of the armature winding, L a the

inductance of the armature winding, i a the armature current, b the generator voltage

constant (back-emf) and ω the angular velocity of the shaft. The resulting torque

is found from the generated torque minus the moment of inertia of the armature

and the frictional moment.