Page 169 - Mechatronic Systems Modelling and Simulation with HDLs

P. 169

158 7 MECHATRONICS

• Finally, when the product is with the customer, i.e. a disk drive company, or

even in the field, the analysis of spurious behaviour on the system model is

much easier for application engineers, since every signal or quantity is visible.

Unfortunately, this does not cover all possible faults of a device, since imple-

mentation related effects are not taken into account in system modelling. On

the other hand, with adequate fault modelling it should be easy to prove or

disprove any hypothesis that the application engineers may have on the root

cause of system failures.

In the following, this will be illustrated on the basis of the example of the servo

control of a disk drive system.

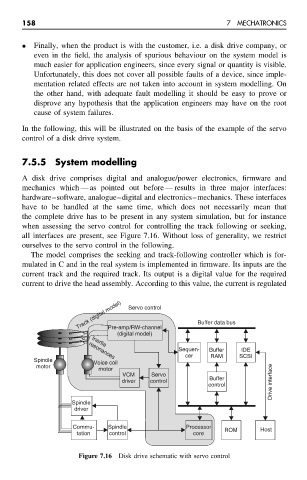

7.5.5 System modelling

A disk drive comprises digital and analogue/power electronics, firmware and

mechanics which — as pointed out before — results in three major interfaces:

hardware–software, analogue–digital and electronics–mechanics. These interfaces

have to be handled at the same time, which does not necessarily mean that

the complete drive has to be present in any system simulation, but for instance

when assessing the servo control for controlling the track following or seeking,

all interfaces are present, see Figure 7.16. Without loss of generality, we restrict

ourselves to the servo control in the following.

The model comprises the seeking and track-following controller which is for-

mulated in C and in the real system is implemented in firmware. Its inputs are the

current track and the required track. Its output is a digital value for the required

current to drive the head assembly. According to this value, the current is regulated

Track (digital model) Servo control Buffer data bus

Pre-amp/RW-channel

(digital model)

Inertia

Sequen- Buffer IDE

cer RAM SCSI

resonances

Spindle Voice coil

motor

motor

VCM Servo

driver control Buffer Drive interface

control

Spindle

driver

Commu- Spindle Processor ROM Host

tation control core

Figure 7.16 Disk drive schematic with servo control