Page 177 - Mechatronic Systems Modelling and Simulation with HDLs

P. 177

166 8 MICROMECHATRONICS

compressive or tensile stresses, the modulus of elasticity, or the dielectric con-

stants. In some cases no values can be found in the literature. For example, the

modulus of elasticity of polycrystalline silicon depends, amongst other things, upon

its grain structure and its doping, and thus has to be determined individually for

each case. This typically occurs on the basis of test structures, which are used for

parameter extraction and are incorporated into process control, as in microelec-

tronics, see for example Kiesewetter et al. [192] or Voigt et al. [415]. If no precise

values can be provided here, the reliability of the simulation is jeopardised.

The two demonstrators represented in the following describe the structural mod-

elling for a circuit simulator based upon finite elements. The first example relates

to a capacitive pressure sensor in surface micromechanics, see Dudaicevs et al.

[87] and [88]. The second example is an actuator in the form of a micromirror,

which is arranged in an array on a chip, can be deflected individually, and in this

manner generates pixel images for all types of displays, see K¨ uck et al. [209],

Younse [433] and Bielefeld et al. [29].

8.2 Demonstrator 5: Capacitive Pressure Sensor

8.2.1 System description

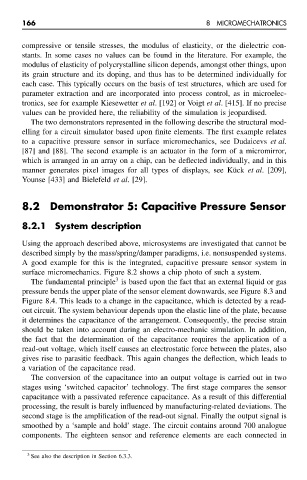

Using the approach described above, microsystems are investigated that cannot be

described simply by the mass/spring/damper paradigms, i.e. nonsuspended systems.

A good example for this is the integrated, capacitive pressure sensor system in

surface micromechanics. Figure 8.2 shows a chip photo of such a system.

3

The fundamental principle is based upon the fact that an external liquid or gas

pressure bends the upper plate of the sensor element downwards, see Figure 8.3 and

Figure 8.4. This leads to a change in the capacitance, which is detected by a read-

out circuit. The system behaviour depends upon the elastic line of the plate, because

it determines the capacitance of the arrangement. Consequently, the precise strain

should be taken into account during an electro-mechanic simulation. In addition,

the fact that the determination of the capacitance requires the application of a

read-out voltage, which itself causes an electrostatic force between the plates, also

gives rise to parasitic feedback. This again changes the deflection, which leads to

a variation of the capacitance read.

The conversion of the capacitance into an output voltage is carried out in two

stages using ‘switched capacitor’ technology. The first stage compares the sensor

capacitance with a passivated reference capacitance. As a result of this differential

processing, the result is barely influenced by manufacturing-related deviations. The

second stage is the amplification of the read-out signal. Finally the output signal is

smoothed by a ‘sample and hold’ stage. The circuit contains around 700 analogue

components. The eighteen sensor and reference elements are each connected in

3 See also the description in Section 6.3.3.