Page 172 - Mechatronics for Safety, Security and Dependability in a New Era

P. 172

Ch32-I044963.fm Page 156 Monday, August 7, 2006 11:28 AM

Ch32-I044963.fm

156

156 Page 156 Monday, August 7,2006 11:28 AM

volume usually has simple shape as shown in Figure 2, we can estimate accurately interference

between c,y m and the tool swept volume. As a result, the existence evaluation for workpiece volume in

machining is realized without the estimation of worikpiece shape. It means the instantaneous cutting

force can be predicted directly without the estimation of explicit workpiece shape. By using the

proposed algorithm, we can predict the cutting error on the nominal workpiece surface regardless of

the order of tool movement.

EVALUATION OF THE PROPOSED PROCEDURE AND CONCLUSION

In order to evaluate the proposed procedure, we develop a prototype system and conduct an

experiment using NC program simulates finish machining. In the prototype system, we introduced

P-Voxel representation method (Kaneko J. 2002) in order to accelerate the existence evaluation.

10 10

0 0

[μm] [μm]

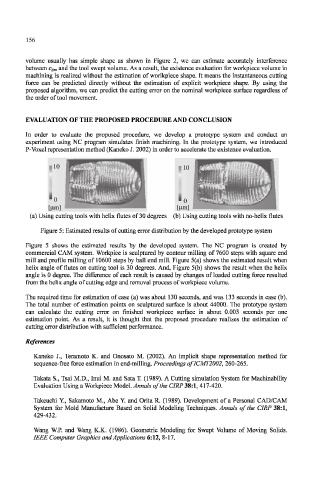

(a) Using cutting tools with helix flutes of 30 degrees (b) Using cutting tools with no-helix flutes

Figure 5: Estimated results of cutting error distribution by the developed prototype system

Figure 5 shows the estimated results by the developed system. The NC program is created by

commercial CAM system. Workpice is sculptured by contour milling of 7600 steps with square end

mill and profile milling of 10600 steps by ball end mill. Figure 5(a) shows the estimated result when

helix angle of flutes on cutting tool is 30 degrees. And, Figure 5(b) shows the result when the helix

angle is 0 degree. The difference of each result is caused by changes of loaded cutting force resulted

from the helix angle of cutting edge and removal process of workpiece volume.

The required time for estimation of case (a) was about 130 seconds, and was 133 seconds in case (b).

The total number of estimation points on sculptured surface is about 44000. The prototype system

can calculate the cutting error on finished workpiece surface in about 0.003 seconds per one

estimation point. As a result, it is thought that the proposed procedure realizes the estimation of

cutting error distribution with sufficient performance.

References

Kaneko J., Teramoto K. and Onosato M. (2002). An implicit shape representation method for

sequence-free force estimation in end-milling. Proceedings oflCMT2002, 260-265.

Takata S., Tsai M.D., Inui M. and Sata T. (1989). A Cutting simulation System for Machinability

Evaluation Using a Workpiece Model. Annals of the CIRP 38:1, 417-420.

Takeuchi Y., Sakamoto M., Abe Y. and Orita R. (1989). Development of a Personal CAD/CAM

System for Mold Manufacture Based on Solid Modeling Techniques. Annals of the CIRP 38:1,

429-432.

Wang W.P. and Wang K.K. (1986). Geometric Modeling for Swept Volume of Moving Solids.

IEEE Computer Graphics and Applications 6:12, 8-17.