Page 175 - Mechatronics for Safety, Security and Dependability in a New Era

P. 175

Ch33-I044963.fm Page 159 Tuesday, August 1, 2006 3:12 PM

Tuesday, August

3:12 PM

1, 2006

Ch33-I044963.fm

Page 159

159

159

PC

Linear scale PC

Linear scale

Motor driver

EDM head

Pulleys

Ball screw

h

SL L1

Shaft

Tabular jig Servomotor Ls1 Ls2 L2

Working fluid Wires

SL

Helical

compression SL

spring

L-shaped

jig

Electrode Workpiece

Electrode

Workpiece

(b) In

(a) Initial stage

(a) Initial stage (b) In feeding

feeding

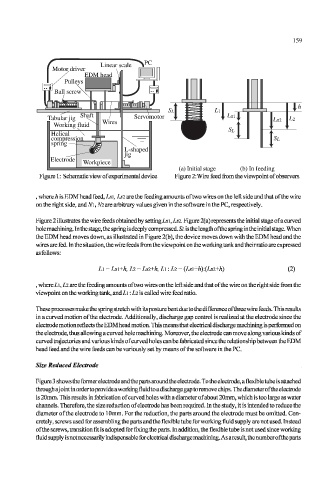

Figure 1: Schematic view of experimental device Figure 2: Wire feed from the viewpoint of observers

, where h is EDM head feed, Lsi, Lsi are the feeding amounts of two wires on the left side and that of the wire

on the right side, and M, Ni are arbitrary values given in the software in the PC, respectively.

Figure 2 illustrates the wire feeds obtained by seUingLsi,Ls2. Figure 2(a) represents the initial stage of a curved

hole machining. In the stage, the spring is deeply compressed. Si. is the length ofthe spring in the initial stage. When

the EDM head moves down, as illustrated in Figure 2(b), the device moves down with the EDM head and the

wires are fed. In the situation, the wire feeds from the viewpoint on the working tank and their ratio are expressed

as follows:

L\ = Ls\+h, Ll = Ls2+h, L\:Ll = (Ls\+h):(Ls2+h) (2)

, where L\, Li are the feeding amounts of two wires on the left side and that ofthe wire on the right side from the

viewpoint on the working tank, and L\: Li is called wire feed ratio.

These processes make the spring stretch with its posture bent due to the difference of three wire feeds. This results

in a curved motion ofthe electrode. Additionally, discharge gap control is realized at the electrode since the

electrode motion reflects the EDM head motion. This means that electrical discharge machining is performed on

the electrode, thus allowing a curved hole machining. Moreover, the electrode can move along various kinds of

curved trajectories and various kinds of curved holes can be fabricated since the relationship between the EDM

head feed and the wire feeds can be variously set by means ofthe software in the PC.

Size Reduced Electrode

Figure 3 shows the former electrode and the parts around the electrode. To the electrode, a flexible tube is attached

through a j oint in order to provide a working fluid to a discharge gap to remove chips. The diameter ofthe electrode

is 20mm. This results in fabrication of curved holes with a diameter of about 20mm, which is too large as water

channels. Therefore, the size reduction of electrode has been required. In the study, it is intended to reduce the

diameter ofthe electrode to 10mm. For the reduction, the parts around the electrode must be omitted. Con-

cretely, screws used for assembling the parts and the flexible tube for working fluid supply are not used. Instead

ofthe screws, transition fit is adopted for fixing the parts. In addition, the flexible tube is not used since working

fluid supply is not necessarily indispensable for electrical discharge machining. Asa result, the number ofthe parts