Page 180 - Mechatronics for Safety, Security and Dependability in a New Era

P. 180

Ch34-I044963.fm Page 164 Thursday, July 27, 2006 7:23 AM

Ch34-I044963.fm

164

164 Page 164 Thursday, July 27, 2006 7:23 AM

INTRODUCTION

In recent years, many kinds of metals are applied to medical usages instead of ceramics, high polymer and

so on. Metals have the advantage in terms of strength, elasticity and stiffness. Usually employed metals

are stainless steel, cobalt-chromium alloy, titanium, gold and so forth. Naturally, these metals are widely

employed as materials of such medical implements as are buried in human bodies, for example, fixture

for fracture, artificial joints, tooth implants, and others. Accordingly, it is important to investigate the

influences or toxicities of the metals for human bodies. For satisfactory selection of metals used in the

medical implements, therefore, it is essential to evaluate bio- and blood- compatibilities of the metals.

Conventionally, the evaluation has been done by making experiments on living animals, which consumes

a lot of money and time. To save the cost, it is required to develop a new evaluating method.

On the other hand, micro-rheology device to measure blood-fluidity has been developed to investigate

flow mechanism of blood. The device allows human blood flow to pass through microcharmel array built

on a chip, which is a model of capillary vessels due to its shape in which many microgrooves are arranged

in parallel. At the same time, the blood flow through the microchannel array can be visually observed,

which can evaluate its fluidity.

Consequently, the employment of microchannel array chips made of various metals is expected to evalu-

ate the compatibility between blood and metals. However, the microgrooves constituting a microchannel

array is generally built on silicon by photolithographic techniques, which do not have high abilities to

control the shape of the microgrooves and to increase the accuracy of the shape. Their shape and accuracy

are extremely important to measure blood-fluidity with a microchannel array chip.

Accordingly, the study aims at fabrication of the microchannel array chip by ultraprecision cutting. Cut-

ting can make complicated microgroove shapes with high degree of freedom and high accuracy, and have

no choice of materials to be fabricated, Takeuchi et al., (2001) and (2002), Kumon et al., (2002). As a

result of actual machining experiments, it is succeeded to fabricate chips with two-kinds-shaped

microchannel array made of some metals by means of ultraprecision cutting.

ULTRAPRECISION MACHINING CENTER AND MACHINING METHOD

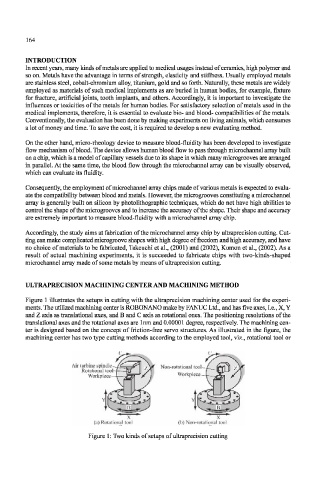

Figure 1 illustrates the setups in cutting with the ultraprecision machining center used for the experi-

ments. The utilized machining center is ROBONANO make by FANUC Ltd., and has five axes, i.e., X, Y

and Z axis as translational axes, and B and C axis as rotational ones. The positioning resolutions of the

translational axes and the rotational axes are 1 nm and 0.00001 degree, respectively. The machining cen-

ter is designed based on the concept of friction-free servo structures. As illustrated in the figure, the

machining center has two type cutting methods according to the employed tool, viz., rotational tool or

Air turbine spindle Non-rotational tool

Rotational tool

Workpiece Workpiece

(a) Rotational tool (b) Non-rotational tool

Figure 1: Two kinds of setups of ultraprecision cutting