Page 181 - Mechatronics for Safety, Security and Dependability in a New Era

P. 181

Ch34-I044963.fm Page 165 Thursday, July 27, 2006 7:23 AM

Page 165

7:23 AM

Ch34-I044963.fm

Thursday, July 27, 2006

165

165

non-rotational tool. The former is attached to a high speed air turbine spindle mounted on C table. The

latter is directly fixed on C table through a jig. A workpiece is mounted on B table in both cases.

CREATION OF V-SHAPED MICROCHANNEL ARRAY CHIP

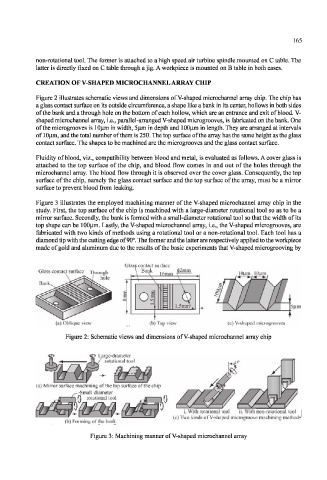

Figure 2 illustrates schematic views and dimensions of V-shaped microchannel array chip. The chip has

a glass contact surface on its outside circumference, a shape like a bank in its center, hollows in both sides

of the bank and a through hole on the bottom of each hollow, which are an entrance and exit of blood. V-

shaped microchannel array, i.e., parallel-arranged V-shaped microgrooves, is fabricated on the bank. One

of the microgrooves is lOum in width, 5|j.m in depth and lOOum in length. They are arranged at intervals

of 10|im, and the total number of them is 250. The top surface of the array has the same height as the glass

contact surface. The shapes to be machined are the microgrooves and the glass contact surface.

Fluidity of blood, viz., compatibility between blood and metal, is evaluated as follows. A cover glass is

attached to the top surface of the chip, and blood flow comes in and out of the holes through the

microchannel array. The blood flow through it is observed over the cover glass. Consequently, the top

surface of the chip, namely the glass contact surface and the top surface of the array, must be a mirror

surface to prevent blood from leaking.

Figure 3 illustrates the employed machining manner of the V-shaped microchannel array chip in the

study. First, the top surface of the chip is machined with a large-diameter rotational tool so as to be a

mirror surface. Secondly, the bank is formed with a small-diameter rotational tool so that the width of its

top shape can be 100)im. Tastly, the V-shaped microchannel array, i.e., the V-shaped microgrooves, are

fabricated with two kinds of methods using a rotational tool or a non-rotational tool. Each tool has a

diamond tip with the cutting edge of 90°. The former and the latter are respectively applied to the workpiece

made of gold and aluminum due to the results of the basic experiments that V-shaped microgrooving by

Glass contact surface

Glass contac.t surface ough \ Bank . . (|>2mm ,1-OWP,

hole .*_\— \ 16mm

Bank. \

ol

5|im

(a) Oblique view (b) Top view (c) V-shaped microgrooves

Figure 2: Schematic views and dimensions of V-shaped microchannel array chip

Large-diameter

rotational tool

(a) Mirror surface machining of the top surface of the chip

---Small-diameter

\(\ rotational tool

i. With rotational tool ii. With non-rotational tool

(c) Two kinds of V-shaped microgroove machining methods

(b) Forming of the bank

Figure 3: Machining manner of V-shaped microchannel array