Page 182 - Mechatronics for Safety, Security and Dependability in a New Era

P. 182

Ch34-I044963.fm Page 166 Thursday, July 27, 2006 7:23 AM

Ch34-I044963.fm

166

166 Page 166 Thursday, July 27, 2006 7:23 AM

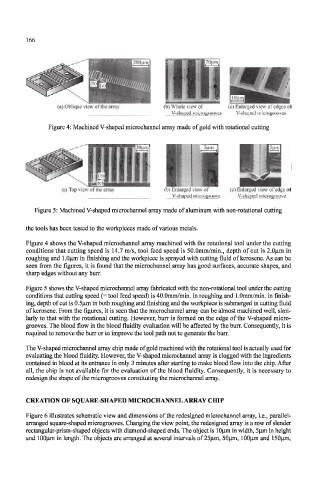

(a) Oblique view of the array (b) Whole view of (c) Enlarged view of edges of

V-shaped microgrooves V-shaped microgrooves

Figure 4: Machined V-shaped microchannel array made of gold with rotational cutting

(a) Top view of the array (b) Enlarged view of (c) Enlarged view of edge of

V-shaped microgroove V-shaped microgroove

Figure 5: Machined V-shaped microchannel array made of aluminum with non-rotational cutting

the tools has been tested to the workpieces made of various metals.

Figure 4 shows the V-shaped microchannel array machined with the rotational tool under the cutting

conditions that cutting speed is 14.7 m/s, tool feed speed is 50.0mm/min., depth of cut is 2.0|i.m in

roughing and 1.0|im in finishing and the workpiece is sprayed with cutting fluid of kerosene. As can be

seen from the figures, it is found that the microchannel array has good surfaces, accurate shapes, and

sharp edges without any burr.

Figure 5 shows the V-shaped microchannel array fabricated with the non-rotational tool under the cutting

conditions that cutting speed (= tool feed speed) is 40.0mm/min. in roughing and l.Omm/min. in finish-

ing, depth of cut is 0.5um in both roughing and finishing and the workpiece is submerged in cutting fluid

of kerosene. From the figures, it is seen that the microchannel array can be almost machined well, simi-

larly to that with the rotational cutting. However, burr is formed on the edge of the V-shaped micro-

grooves. The blood flow in the blood fluidity evaluation will be affected by the burr. Consequently, it is

required to remove the burr or to improve the tool path not to generate the burr.

The V-shaped microchannel array chip made of gold machined with the rotational tool is actually used for

evaluating the blood fluidity. However, the V-shaped microchannel array is clogged with the ingredients

contained in blood at its entrance in only 3 minutes after starting to make blood flow into the chip. After

all, the chip is not available for the evaluation of the blood fluidity. Consequently, it is necessary to

redesign the shape of the microgrooves constituting the microchannel array.

CREATION OF SQUARE-SHAPED MICROCHANNEL ARRAY CHIP

Figure 6 illustrates schematic view and dimensions of the redesigned microchannel array, i.e., parallel-

arranged square-shaped microgrooves. Changing the view point, the redesigned array is a row of slender

rectangular-prism-shaped objects with diamond-shaped ends. The object is 10(im in width, 5(im in height

and 100(im in length. The objects are arranged at several intervals of 25(im, 50[im, 100(im and 150(j,m,