Page 350 - Mechatronics for Safety, Security and Dependability in a New Era

P. 350

Ch68-I044963.fm Page 334 Tuesday, August 1, 2006 8:30 PM

Ch68-I044963.fm

334

334 Page 334 Tuesday, August 1, 2006 8:30 PM

that the on/off valve has a simple configuration and, furthermore, can be a logical interface between a

computer and hydraulic systems. Hence, a low cost and highly reliable system may be developed,

under the recent condition that the systems are equipped with computers.

In the present study, we propose an active control hydro-pneumatic suspension system composed of

high speed on/off solenoid valves which are driven in a PWM (Pulse Width Modulation) digital mode.

In order to realize a robust control system even when measurement errors exist, we adopted a preview

control method equipped with an ADF (adaptive digital filter). The experiment was performed by

using a bench system which physically simulates induced vibrations from the road and also simulates

the body mass of an automobile. The results obtained from the system using preview control with an

ADF were compared with those obtained from a system using a conventional sky-hook control.

CONSTITUTION OF THE ACTIVE SUSPENSION SYSTEM

p p

s s

M M b b

Mb

Valve-1

Va l v e - 1 x b x b

at

Ac

Actuator

or

t

u

p g p g

x g x g

p p a1 p p a2

a2

a1

rin

p

G Gas spring g

a

s s

M M w w x x

Mw

Valve-2

V al ve- 2 w w

K t K t

x x r r

Figure 1: The outline of the system used for the experiment

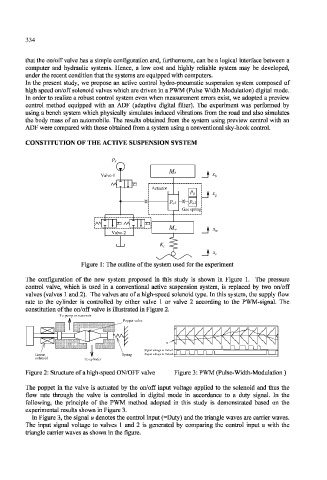

The configuration of the new system proposed in this study is shown in Figure 1. The pressure

control valve, which is used in a conventional active suspension system, is replaced by two on/off

valves (valves 1 and 2). The valves are of a high-speed solenoid type. In this system, the supply flow

rate to the cylinder is controlled by either valve 1 or valve 2 according to the PWM-signal. The

constitution of the on/off valve is illustrated in Figure 2.

o pump or reservoir

To pump or reservoir

Poppet valve

Poppet valve

u u

a

a

o

e t

g

V

na

g

l

v

o

Si Signal voltage to Valve1 e 1

t

lv

l

a

V

lv

o

na

l

v

Linear Spring Si Signal voltage to Valve2 e 2

Spring

g

a

g

e t

o

l

t

solenoid To cylinder

cylinder

Figure 2: Structure of a high-speed ON/OFF valve Figure 3: PWM (Pulse-Width-Modulation )

The poppet in the valve is actuated by the on/off input voltage applied to the solenoid and thus the

flow rate through the valve is controlled in digital mode in accordance to a duty signal. Tn the

following, the principle of the PWM method adopted in this study is demonstrated based on the

experimental results shown in Figure 3.

In Figure 3, the signal u denotes the control input (=Duty) and the triangle waves are carrier waves.

The input signal voltage to valves 1 and 2 is generated by comparing the control input u with the

triangle carrier waves as shown in the figure.