Page 138 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 138

112 Membranesfor Industrial Wastewater Recoverg and Re-use

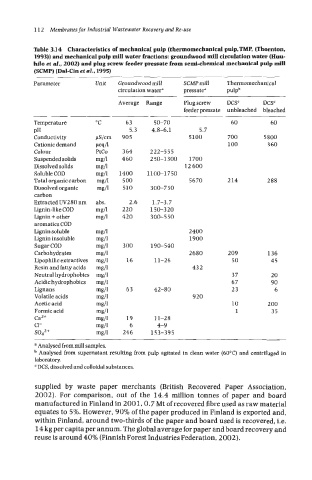

Table 3.14 Characteristics of mechanical pulp (thermomechanical pulp, TMP, (Thornton,

1993)) and mechanical puIp mill water fractions: groundwood mill circulation water (Huu-

hilo et aJ., 2002) and plug screw feeder pressate from semi-chemical mechanical palp mill

(SCMP) (Dal-Cin et aJ., 1995)

Parameter Unit Groundwood mill SCMP mill Thermomechanical

circulation watera pressated pulpb

Average Range Plug screw DCSC DCSC

feeder pressate unbleached bleached

Temperature 63 50-70 60 60

PH 5.3 4.8-6.1 5.7

Conductivity 905 5100 700 5800

Cationic demand 100 3 60

Colour 364 222-5 5 5

Suspended solids 460 250-1300 1700

Dissolved solids 12 600

Soluble COD 1400 1100-1750

Total organic carbon 500 5670 214 288

Dissolved organic 510 300-750

carbon

Extracted UV280 nm 2.6 1.7-3.7

Lignin-like COD 220 150-320

Lignin + other 420 300-550

aromatics COD

Lignin soluble 2400

Lignin insoluble 1900

Sugar COD 300 190-540

Carbohydrates 2680 209 136

Lipophilic extractives 16 11-26 50 45

Resin and fatty acids 432

Neutral hydrophobics 37 20

Acidic hydrophobics 67 90

Lignans 63 42-80 23 6

Volatile acids 920

Acetic acid 10 200

Formic acid 1 35

CaZ+ 19 11-28

Cl- 6 4-9

SO2+ 246 153-395

a Analysed from mill samples

Analysed from supernatant resulting from pulp agitated in clean water (60'C) and centrifuged in

laboratory

DCS, dissolved and colloidal substances.

supplied by waste paper merchants (British Recovered Paper Association,

2002). For comparison, out of the 14.4 million tonnes of paper and board

manufactured in Finland in 2001,0.7 Mt of recovered fibre used as raw material

equates to 5%. However, 90% of the paper produced in Finland is exported and,

within Finland, around two-thirds of the paper and board used is recovered, i.e.

14 kg per capita per annum. The global average for paper and board recovery and

reuse is around 40% (Finnish Forest Industries Federation, 2002).