Page 139 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 139

Industrial waters 11 3

Recovered paper loads the water circuit of paper mills with a variety of

adhesives. Colloidal, dissolved, finely dispersed or water-soluble adhesives

originating from recovered fibre are called secondary stickies because they

agglomerate only later in the finished stock through chemical reaction, or else

they appear only on the paper machine thus causing severe problems. In

addition, the alkaline de-inking procedure and a high temperature promote

dissolution of adhesives in the circulation water (Zippel, 2001). It has been

estimated that the total amount of adhesives in DIP (de-inked pulp) is 7 kg/t of

paper, 70 times the maximum permitted level of sticky material allowed in white

paper manufactured from DIP (0.1 kg/t; Zippel, 2001). Volume and quality data

for water from stock preparation of different paper grades using recovered fibre

areshowninTable 3.15.

3.2.4 Current water and effluent purification systems and governing legislation

Driving forces for effluent treatment in the pulp and paper industry can be

categorised as follows:

0 Environmental legislation

0 Better economy

0 Local demands, for example lack of water resources

0 Customer demand

The environmental legislation in the pulp and paper industry is likely to

undergo profound changes within the next few years. The EU Directive on

Integrated Pollution Prevention and Control (IPPC) includes a BAT reference

document, BREF, which refers to the pulp and paper industry. This came into

force in 1999 for greenfield mills, and will apply to existing mills from 2007. The

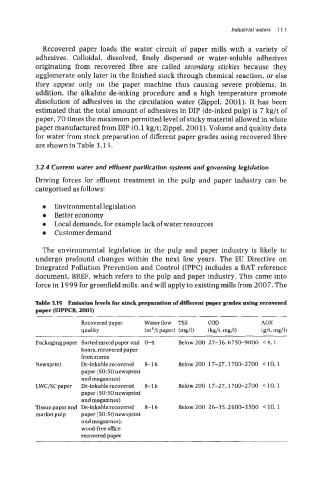

Table 3.15 Emission levels for stock preparation of different paper grades using recovered

paper (EIPPCB, 2001)

Recovered paper Waterflow TSS COD AOX

quality (m3/tpaper) (mg/l) (Wt, rng/l) (pit. mg/U

Packaging paper Sorted mixed paper and 0-4 Below 200 27-36.6750-9000 < 4.1

boars, recovered paper

from stores

Newsprint De-inkable recovered 8-1 6 Below 200 17-27,1700-2700 < 10,l

paper (50:50 newsprint

and magazines)

LWC/SC paper De-inkable recovered 8-16 Below 200 17-27,1700-2700 < 10,l

paper (5O:SO newsprint

and magazines)

Tissue paper and De-inkable recovered 8-1 6 Below200 26-35.2600-3500 <lo, 1

market pulp paper (50:SO newsprint

and magazines):

wood-free office

recovered paper