Page 135 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 135

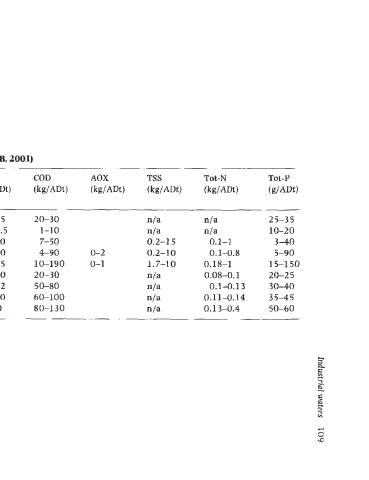

Table 3.10 Different pulping effluents and their flows and quality (EIPPCB, 2001)

Process Etnuent BOD, COD AOX TSS Tot-N Tot-P

volume/flow (kg/ADt) (kg/ADt) (kg/AJJt) (kg/ADt) (kg/ADt) (g/ADt)

(m3/ADt)

Debarking Wet debarking and press 3-10 5-1 5 20-30 nla 2 5-3 5

Dry debarking and press 0.5-2.5 0.5-2.5 1-10 n/a 10-20

Kraft mill Unbleached pulp 20-80 1-20 7-50 0.1-1 3-40

Bleached pulp 30-1 10 0.240 4-90 0-2 0.1-0.8 5-90

Sulphite pulping Bleached and unbleached 40-100 0.5-75 10-190 0-1 0.18-1 15-1 50

Mechanical pulping Groundwood 5-1 5 8.5-10 20-30 0.08-0.1 20-25

TMP 4-10 13-22 50-80 0.1-0.1 3 30-40

CTMP 15-50 17-30 60-100 0.11-0.14 3 5-4 5

Bleached CTMP 25-0 80-130 0.13-0.4 50-60

n/a, not available; ADt. air dried tonne.

3

3

9