Page 272 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 272

Case studies 241

effectively reduces the concentration of all dissolved ions in the flow (Table 5.5).

Total dissolved solids are reduced from 16 12 mg 1-1 to 2 1 7 mg l-', generating a

concentrated stream of 10910 mg 1-'. Specific ionic removals range from 47%

(fluoride) to 96% (magnesium).

Evaporation is a key unit process in achieving ZLDs due to its ability to operate

at high recovery rates from very high TDS waste streams. The technology is

however very expensive and as such an economic driver exists for pre

concentrating the flow in systems like the EDR/RO described above. The EDR/RO

system cost $750 000 to install and resulted in a 64% reduction in the required

capacity of the brine evaporator. The reduction in required capacity of brine

treatment results in a saving of $900000 in capital and $682 day-' in

operational costs (including EDR/RO costs) ($240 000 year-'). The EDR/RO

costs (Table 5.6) include replacement membranes for the EDR in 10 years and

the RO in 2 years. The operating costs of the process equate to $0.12 per 1000

gallon ($0.03 m-3) for the EDR and $0.1 per 1000 gallons ($0.026 mP3) for the

RO. Additional costs savings are made from recycling clean water which reduces

costs and make up water demand.

5.4 VHP Ugchelen: paper mill water recycling (Netherlands)

5.4.1 Background

VHP security paper mill owned by Ugchelen BV, located in Apeldoorn

(Netherlands), produces bank notes and other security papers. The paper mill

uses cotton as its raw material which it bleaches with hydrogen peroxide at a

temperature of approximately 100°C and pH values between 11 and 12. The

process uses a total of 100 m3 of water per ton of paper which at the plant's

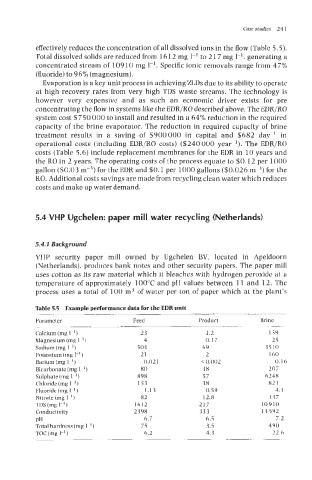

Table 5.5 Example performance data for the EDR unit

Parameter Feed Product Brine

Calcium (mg I-') 23 1.2 159

Magnesium (mg 1-') 4 0.17 25

Sodium (mg 1-l) 504 69 3510

Potassium (mg 1-l) 21 2 160

Barium (mg I-') 0.021 < 0.002 0.16

Bicarbonate (mg I-') 80 38 207

Sulphate (mg I-') 898 57 6248

Chloride (mg I-') 153 38 821

Fluoride (mg I-') 1.13 0.59 4.1

Nitrate (mg I-') 82 12.8 137

TDS (mg 1-') 1612 217 10910

Conductivity 2398 333 13 592

PH 6.7 6.5 7.2

Total hardness (mg I-') 75 3.5 490

TOC (mg I-' ) 6.2 4.3 22.6