Page 276 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 276

Case studies 245

55.2 Description of plant

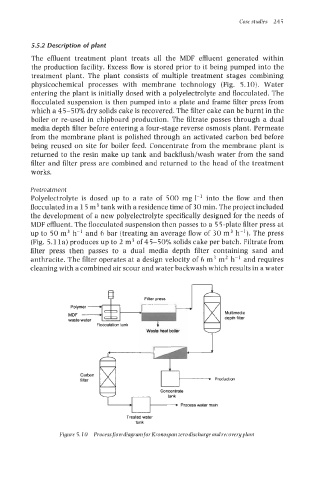

The effluent treatment plant treats all the MDF effluent generated within

the production facility. Excess flow is stored prior to it being pumped into the

treatment plant. The plant consists of multiple treatment stages combining

physicochemical processes with membrane technology (Fig. 5.10). Water

entering the plant is initially dosed with a polyelectrolyte and flocculated. The

flocculated suspension is then pumped into a plate and frame filter press from

which a 45-50% dry solids cake is recovered. The filter cake can be burnt in the

boiler or re-used in chipboard production. The filtrate passes through a dual

media depth filter before entering a four-stage reverse osmosis plant. Permeate

from the membrane plant is polished through an activated carbon bed before

being reused on site for boiler feed. Concentrate from the membrane plant is

returned to the resin make up tank and backflush/wash water from the sand

filter and filter press are combined and returned to the head of the treatment

works.

Pretreatment

Polyelectrolyte is dosed up to a rate of 500 mg 1-1 into the flow and then

flocculated in a 15 m3 tank with a residence time of 30 min. The project included

the development of a new polyelectrolyte specifically designed for the needs of

MDF effluent. The flocculated suspension then passes to a 55-plate filter press at

up to 50 m3 h-' and 6 bar (treating an average flow of 30 m3 h-l). The press

(Fig. 5.11a) produces up to 2 m3 of 45-50% solids cake per batch. Filtrate from

filter press then passes to a dual media depth filter containing sand and

anthracite. The filter operates at a design velocity of 6 m3 m2 h-l and requires

cleaning with a combined air scour and water backwash which results in a water

Multimedla

depth filter

Waste heat boiler

Carbon ,-, PrOduCtiOn

finer

Concentrate

~

Process water main

Treated water

tank

Figure 5. IO Processflow diagram for Kronospan zero discharge and recovery plant