Page 278 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 278

Case studies 247

Water for steam Water m wwd

u (2

Main make up Water in product

(79)

Evaporator loses

Feed stock

(2)

Resin make up

(7 )

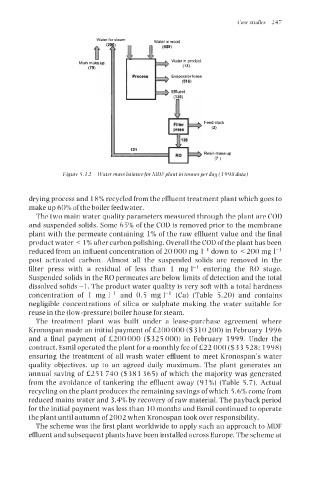

Figure 5.12 Water mass halaricefor MDFplant in tonnesperdag (1 9 98 data)

drying process and 18% recycled from the effluent treatment plant which goes to

make up 60% of the boiler feedwater.

The two main water quality parameters measured through the plant are COD

and suspended solids. Some 65% of the COD is removed prior to the membrane

plant with the permeate containing 1% of the raw effluent value and the final

product water < 1% after carbon polishing. Overall the COD of the plant has been

reduced from an influent concentration of 20 000 mg 1-1 down to < 200 mg I-'

post activated carbon. Almost all the suspended solids are removed in the

filter press with a residual of less than 1 mg 1-1 entering the RO stage.

Suspended solids in the RO permeates are below limits of detection and the total

dissolved solids -1. The product water quality is very soft with a total hardness

concentration of 1 mg 1-l and 0.5 mg 1-l (Ca) (Table 5.20) and contains

negligible concentrations of silica or sulphate making the water suitable for

reuse in the (low-pressure) boiler house for steam.

The treatment plant was built under a lease-purchase agreement where

Kronospan made an initial payment of €200 000 ($310 200) in February 1996

and a final payment of €200 000 ($325 000) in February 1999. Under the

contract, Esmil operated the plant for a monthly fee of€22 000 ($33 528; 1998)

ensuring the treatment of all wash water effluent to meet Kronospan's water

quality objectives, up to an agreed daily maximum. The plant generates an

annual saving of €251 740 ($383 365) of which the majority was generated

from the avoidance of tankering the effluent away (91%) (Table 5.7). Actual

recycling on the plant produces the remaining savings of which 5.6% come from

reduced mains water and 3.4% by recovery of raw material. The payback period

for the initial payment was less than 10 months and Esmil continued to operate

the plant until autumn of 2002 when Kronospan took over responsibility.

The scheme was the first plant worldwide to apply such an approach to MDF

effluent and subsequent plants have been installed across Europe. The scheme at