Page 283 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 283

2 52 Membranes for Industrial Wastewater Recovery and Re-use

Cleaning chemical

Dye barn

effluent

discharge

Figure 5.15 Processflow diagram for Forsell and SonsLtddye bath waste recyclingplant

, --

i

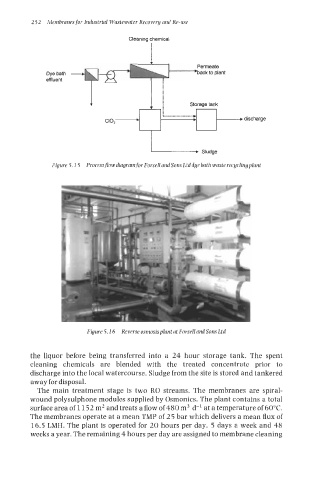

Figure 5.16 Reverseosniosisplant at ForsellandSons Ltd

the liquor before being transferred into a 24 hour storage tank. The spent

cleaning chemicals are blended with the treated concentrate prior to

discharge into the local watercourse. Sludge from the site is stored and tankered

away for disposal.

The main treatment stage is two RO streams. The membranes are spiral-

wound polysulphone modules supplied by Osmonics. The plant contains a total

surface area of 11 52 m2 and treats a flow of 480 m3 d-l at a temperature of 60°C.

The membranes operate at a mean TMP of 2 5 bar which delivers a mean flux of

16.5 LMH. The plant is operated for 20 hours per day, 5 days a week and 48

weeks a year. The remaining 4 hours per day are assigned to membrane cleaning