Page 279 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 279

248 Membranes for lndustrial Wastewater Recovery and Re-use

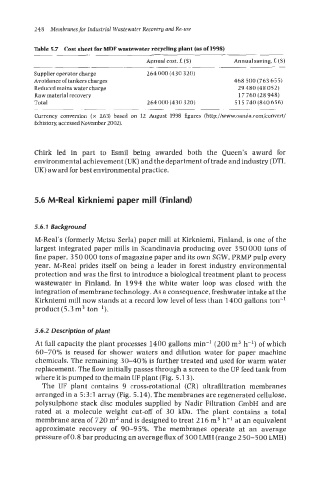

Table 5.7 Cost sheet for MDF wastewater recycling plant (as of 1998)

Annual cost. E (S) Annual saving, E (S)

Supplier operator charge 264 000 (430 320)

Avoidance of tankers charges 468 500 (763 655)

Reduced mains water charge 29 480 (48 052)

Raw material recovery 17 760 (28 948)

Total 264 000 (430 320) 515 740(840656)

Currency conversion (x 1.63) based on 12 August 1998 figures (http://www.oanda.com/convert/

fxhistory, accessed November 2002).

Chirk led in part to Esmil being awarded both the Queen’s award for

environmental achievement (UK) and the department of trade and industry (DTI,

UK) award for best environmental practice.

5.6 M-Real Kirkniemi paper mill (Finland)

5.6.7 Background

M-Real’s (formerly Metsa Serla) paper mill at Kirkniemi, Finland, is one of the

largest integrated paper mills in Scandinavia producing over 3 50 000 tons of

fine paper, 350 000 tons of magazine paper and its own SGW, PRMP pulp every

year. M-Real prides itself on being a leader in forest industry environmental

protection and was the first to introduce a biological treatment plant to process

wastewater in Finland. In 1994 the white water loop was closed with the

integration of membrane technology. As a consequence, freshwater intake at the

Kirkniemi mill now stands at a record low Ievel of less than 1400 gallons ton-I

product (5.3 m3 ton-l).

5.6.2 Description of plant

At full capacity the plant processes 1400 gallons min-l (200 m3 h-l) of which

60-70% is reused for shower waters and dilution water for paper machine

chemicals. The remaining 30-40% is further treated and used for warm water

replacement. The flow initially passes through a screen to the UF feed tank from

where it is pumped to the main UF plant (Fig. 5.1 3).

The UF plant contains 9 cross-rotational (CR) ultrafiltration membranes

arranged in a 5:3:1 array (Fig. 5.14). The membranes are regenerated cellulose,

polysulphone stack disc modules supplied by Nadir Filtration GmbH and are

rated at a molecule weight cut-off of 30 kDa. The plant contains a total

membrane area of 720 m2 and is designed to treat 2 16 m3 h-l at an equivalent

approximate recovery of 90-95%. The membranes operate at an average

pressure of 0.8 bar producing an average flux of 300 LMH (range 2 50-500 LMH)