Page 274 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 274

(a) (b)

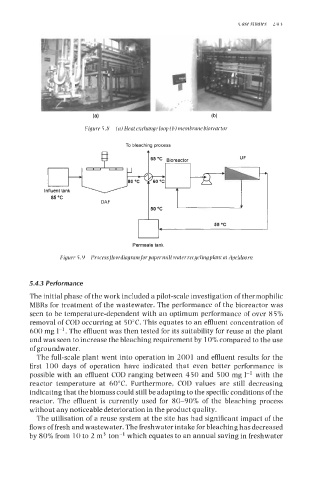

Figure 5.X (a) Heat rxchange loop (b) mrmbranr bioreactor

Influent tank A

85 "C

DAF

55 "C

4

5.4.3 Performance

The initial phase of the work included a pilot-scale investigation of thermophilic

MBRs for treatment of the wastewater. The performance of the bioreactor was

seen to be temperature-dependent with an optimum performance of over 85%

removal of COD occurring at 50°C. This equates to an effluent concentration of

600 mg 1-'. The effluent was then tested for its suitability for reuse at the plant

and was seen to increase the bleaching requirement by 10% compared to the use

of groundwater.

The full-scale plant went into operation in 2001 and effluent results for the

first 100 days of operation have indicated that even better performance is

possible with an effluent COD ranging between 450 and 500 mg 1-1 with the

reactor temperature at 60°C. Furthermore, COD values are still decreasing

indicating that the biomass could still be adapting to the specific conditions of the

reactor. The effluent is currently used for 80-90% of the bleaching process

without any noticeable deterioration in the product quality.

The utilisation of a reuse system at the site has had significant impact of the

flows of fresh and wastewater. The freshwater intake for bleaching has decreased

by 80% from 10 to 2 m3 ton-' which equates to an annual saving in freshwater