Page 286 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 286

Case studies 2 5 5

is constantly looking for ways to reduce its water consumption whilst

maintaining product quality. A number of approaches have been considered to

reduce water demand:

0 Rainwater recycling

0 Well water supply

0 Refrigerator and subfloor condensation recycling

0 Wastewater recycling

The final preference was for wastewater recycling as it provided the most

secure source of water available to the plant. Three applications were identified

for the water including pre washing of product materials, cooling units and floor

washing and boiler feedwater. The projected demand for each application was

40 tonnes day-' which was anticipated to require 140 tonnes day-1 in total of

untreated wastewater to allow for losses during recovery.

5.8.2 Description of plant

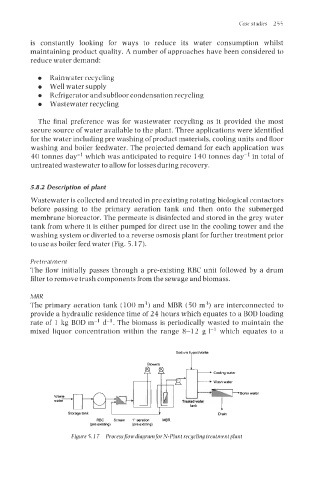

Wastewater is collected and treated in pre existing rotating biological contactors

before passing to the primary aeration tank and then onto the submerged

membrane bioreactor. The permeate is disinfected and stored in the grey water

tank from where it is either pumped for direct use in the cooling tower and the

washing system or diverted to a reverse osmosis plant for further treatment prior

to use as boiler feed water (Fig. 5.1 7).

Pretreatment

The flow initially passes through a pre-existing RBC unit followed by a drum

filter to remove trash components from the sewage and biomass.

MBR

The primary aeration tank (100 m3) and MBR (50 m3) are interconnected to

provide a hydraulic residence time of 24 hours which equates to a BOD loading

rate of 1 kg BOD m-' d-'. The biomass is periodically wasted to maintain the

mixed liquor concentration within the range 8-12 g 1-1 which equates to a

Storage tank I

DlXl"

REC Screen I'aeratm MER

(pe easm) (pre ensting)

Figure 5.17 Processjlow diagram for N-Plant recycling treatment plant