Page 289 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 289

258 Membranes for lndiistrial Wastewater Recovery and Re-use

of the groundwater has also deteriorated (Table 5.12) such that the Flemish

government has forced companies in the region to severely reduce abstraction

volumes.

To maintain production and enable any future expansions requires both

conservation and reuse to be considered. Specific items adopted at the Pasfrost

site include:

0 Partial reuse of wash water for low-grade application which has decreased

the specific water use from 5 down to 3.5 m3 tonne-' of product.

0 Steam peeling instead of caustic peeling to reduce the salt concentration in

the waste water.

0 Anaerobic pretreatment and extension of aerobic treatment producing a

more stable effluent suitable for further treatment and reuse.

By reusing treated wastewater the groundwater demand has been reduced by

50%, equating to a specific water consumption of 2 m3 tonne-' of product.

Specific concerns with the requirements of a reclamation plant were the need to

handle feedwaters with highly variable organics levels, minimise operational

costs and achieve high membrane life expectancy. A core element to the design of

the reclamation facility was the ability to deliver a constant quality feed to the

advanced treatment processes.

Overall, introduction of the reuse options has reduced the groundwater

requirement to 100000 m3 y-' with 200000 m3 y-l coming from reuse of

partially-treated wastewater and 100 000 m3 y-l from the advanced water

treatment plant (Fig. 5.19). Discharge from the site is 100 000 m3 y-' of which

50% is evaporation and 50% is discharge from the treatment works.

5.9.2 Description of plant

The flow initially passes through a screen and a heat exchanger to raise the

average temperature from 20 to 30°C as a pretreatment for the anaerobic stage.

The anaerobic reactor is a 5000 m3 UASB operated at a specific loading rate of

3-6 kg COD m-3 d-l enabling a total of 30 000 kg COD to be treated per day. The

produced biogas is used for heating the incoming flow and has an equivalent

steam rating of 70 tonnes day-' based on the production of 5000-6000 m3 d-l

of biogas during high loads.

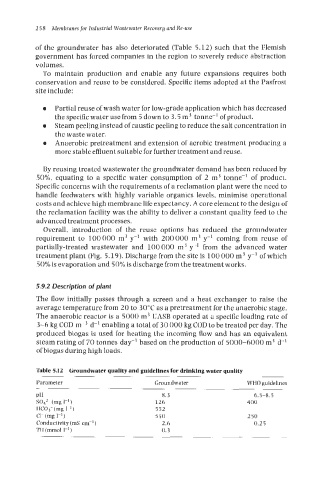

Table 5.12 Groundwater quality and guidelines for drinking water quality

Parameter Groundwater WHO guidelines

PH 8.3 6.5-8.5

S042- (mg I-') 126 400

HC03-(mg 1-') 552

C1- (mg 1-I) 550 250

Conductivity (ms cm-l) 2.6 0.25

TH (mmol 1-I) 0.3