Page 290 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 290

Case studies 259

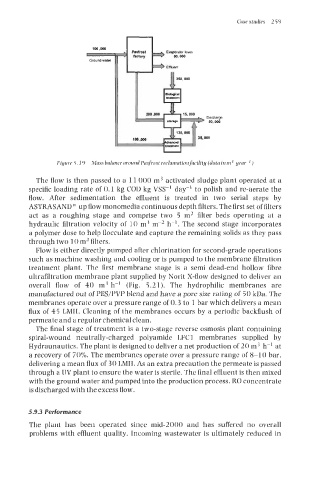

Figure 5.19 Mass balance aroirrld Pasfrost reclamation facility (data in 171 year-’)

The flow is then passed to a 11 000 m3 activated sludge plant operated at a

specific loading rate of 0.1 kg COD kg VSS-l day-’ to polish and re-aerate the

flow. After sedimentation the effluent is treated in two serial steps by

ASTRASAND”’ up flow monomedia continuous depth filters. The first set of filters

act as a roughing stage and comprise two 5 m2 filter beds operating at a

hydraulic filtration velocity of 10 m3 m-2 h-l. The second stage incorporates

a polymer dose to help flocculate and capture the remaining solids as they pass

through two 10 m’ filters.

Flow is either directly pumped after chlorination for second-grade operations

such as machine washing and cooling or is pumped to the membrane filtration

treatment plant. The first membrane stage is a semi dead-end hollow fibre

ultrafiltration membrane plant supplied by Norit X-flow designed to deliver an

overall flow of 40 m3 h-’ (Fig. 5.21). The hydrophilic membranes are

manufactured out of PESJPVP blend and have a pore size rating of 50 kDa. The

membranes operate over a pressure range of 0.3 to 1 bar which delivers a mean

flux of 45 LMH. Cleaning of the membranes occurs by a periodic backflush of

permeate and a regular chemical clean.

The final stage of treatment is a two-stage reverse osmosis plant containing

spiral-wound neutrally-charged polyamide LFCl membranes supplied by

Hydraunautics. The plant is designed to deliver a net production of 20 m3 h-l at

a recovery of 70%. The membranes operate over a pressure range of 8-10 bar,

delivering a mean flux of 30 LMH. As an extra precaution the permeate is passed

through a UV plant to ensure the water is sterile. The final effluent is then mixed

with the ground water and pumped into the production process. RO concentrate

is discharged with the excess flow.

5.9.3 Performance

The plant has been operated since mid-2000 and has suffered no overall

problems with effluent quality. Incoming wastewater is ultimately reduced in