Page 294 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 294

Case studies 263

A

PAINTTANK -+ A A A A A A &”l A

I,

UF :Ulb.nlb.1.

UFR : Ult~lttnb ncycle

DW :Deminenliud water

RP : Recoverad paint

RW : Recovered water

T

ULTRAFILTRATION SYSTEMS

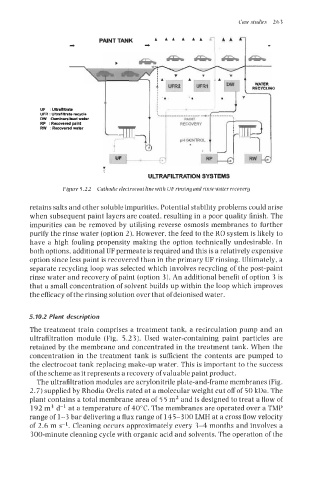

Figure 5.22 Cnthonir electrocoat line with UF rinsingand rinse water recovery

retains salts and other soluble impurities. Potential stability problems could arise

when subsequent paint layers are coated, resulting in a poor quality finish. The

impurities can be removed by utilising reverse osmosis membranes to further

purify the rinse water (option 2). However, the feed to the RO system is likely to

have a high fouling propensity making the option technically undesirable. In

both options, additional UF permeate is required and this is a relatively expensive

option since less paint is recovered than in the primary UF rinsing. Ultimately, a

separate recycling loop was selected which involves recycling of the post-paint

rinse water and recovery of paint (option 3). An additional benefit of option 3 is

that a small concentration of solvent builds up within the loop which improves

the efficacy of the rinsing solution over that of deionised water.

5.70.2 Plant description

The treatment train comprises a treatment tank, a recirculation pump and an

ultrafiltration module (Fig. 5.2 3). Used water-containing paint particles are

retained by the membrane and concentrated in the treatment tank. When the

concentration in the treatment tank is sufficient the contents are pumped to

the electrocoat tank replacing make-up water. This is important to the success

of the scheme as it represents a recovery of valuable paint product.

The ultrafiltration modules are acrylonitrile plate-and-frame membranes (Fig.

2.7) supplied by Rhodia Orelis rated at a molecular weight cut off of 50 kDa. The

plant contains a total membrane area of 5 5 m2 and is designed to treat a flow of

192 m3 d-’ at a temperature of 40°C. The membranes are operated over a TMP

range of 1-3 bar delivering a flux range of 145-300 LMH at a cross flow velocity

of 2.6 m s-l. Cleaning occurs approximately every 3-4 months and involves a

300-minute cleaning cycle with organic acid and solvents. The operation of the