Page 296 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 296

Case studies 2 6 5

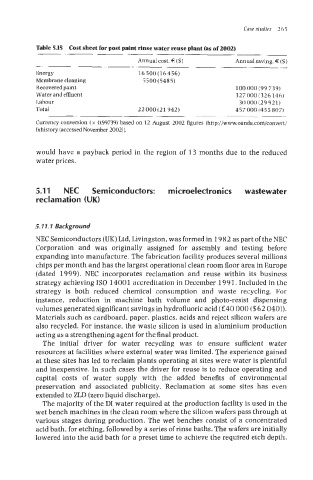

Table 5.15 Cost sheet for post paint rinse water reuse plant (as of 2002)

Annual cost, € ($) Annual saving, € ($)

Energy 16 500 (16456)

Membrane cleaning 5500 (5485)

Recovered paint 100 000 (99 739)

Water and effluent 327000(326 146)

Labour 30 000 (29 921)

Total 22 000 (21 942) 457000 (455 807)

Currency conversion (x 0.99739) based on 12 August 2002 figures (http://www.oanda.com/convert/

fxhistory (accessed November 2002)).

would have a payback period in the region of 13 months due to the reduced

water prices.

5.1 1 NEC Semiconductors: microelectronics wastewater

reclamation (UK)

5.11.1 Background

NEC Semiconductors (UK) Ltd, Livingston, was formed in 1982 as part ofthe NEC

Corporation and was originally assigned for assembly and testing before

expanding into manufacture. The fabrication facility produces several millions

chips per month and has the largest operational clean room floor area in Europe

(dated 1999). NEC incorporates reclamation and reuse within its business

strategy achieving IS0 14001 accreditation in December 1991. Included in the

strategy is both reduced chemical consumption and waste recycling. For

instance, reduction in machine bath volume and photo-resist dispensing

volumes generated significant savings in hydrofluoric acid (€40 000 ($62 040)).

Materials such as cardboard, paper, plastics, acids and reject silicon wafers are

also recycled. For instance, the waste silicon is used in aluminium production

acting as a strengthening agent for the final product.

The initial driver for water recycling was to ensure sufficient water

resources at facilities where external water was limited. The experience gained

at these sites has led to reclaim plants operating at sites were water is plentiful

and inexpensive. In such cases the driver for reuse is to reduce operating and

capital costs of water supply with the added benefits of environmental

preservation and associated publicity. Reclamation at some sites has even

extended to ZLD (zero liquid discharge).

The majority of the DI water required at the production facility is used in the

wet bench machines in the clean room where the silicon wafers pass through at

various stages during production. The wet benches consist of a concentrated

acid bath, for etching, followed by a series of rinse baths. The wafers are initially

lowered into the acid bath for a preset time to achieve the required etch depth.