Page 299 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 299

268 Membranesfor Industrial Wastewater Recovery and Re-use

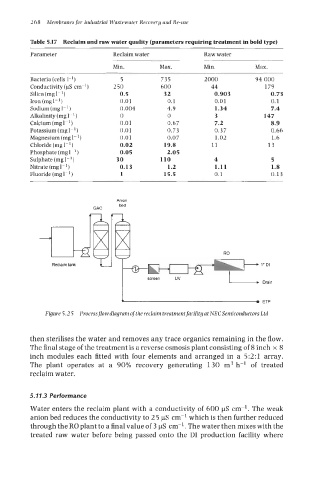

Table 5.17 Reclaim and raw water quality (parameters requiring treatment in bold type)

Parameter Reclaim water Raw water

Min. Max. Min. Max.

Bacteria (cells 1-l) 5 73 5 2000 94 000

Conductivity (pS cm-') 250 600 44 179

Silica (mg 1-') 0.5 32 0.903 0.73

Iron (mg I-') 0.01 0.1 0.01 0.1

Sodium (mg 1-I) 0.004 4.9 1.34 7.4

Alkalinity (mg I-') 0 0 3 147

Calcium (mg 1-l) 0.01 0.67 7.2 8.9

Potassium (mg I-' 0.01 0.73 0.37 0.66

Magnesium (mg 1- ) 0.01 0.07 1.02 1.6

Chloride (mg 1-I) 0.02 19.8 11 13

Phosphate (mg 1-' 0.05 2.05

Sulphate (mg 1-') 30 110 4 5

Nitrate (mg I-') 0.13 1.2 1.11 1.8

Fluoride (mg 1-I) 1 15.5 0.1 0.13

Anion

GAC

RO

I

Reclaim tank I 1"DI

Reclaim tank

I

screen

screen UV

UV

Drain

c ETP

Figure 5.25 Processflow diagram of the reclaim treatment facility at NEC Semiconductors Ltd

then sterilises the water and removes any trace organics remaining in the flow.

The final stage of the treatment is a reverse osmosis plant consisting of 8 inch x 8

inch modules each fitted with four elements and arranged in a 5:2:1 array.

The plant operates at a 90% recovery generating 130 m3 h-' of treated

reclaim water.

5.113 Performance

Water enters the reclaim plant with a conductivity of 600 pS cm-l. The weak

anion bed reduces the conductivity to 2 5 pS cm-l which is then further reduced

through the RO plant to a final value of 3 pS cm-l. The water then mixes with the

treated raw water before being passed onto the DI production facility where