Page 298 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 298

Case studies 267

Waste

backwash

basin

RW water

Flocculator

Alkaline bnne regenerant Dual media

filter

I'D1

plant

I'

:;

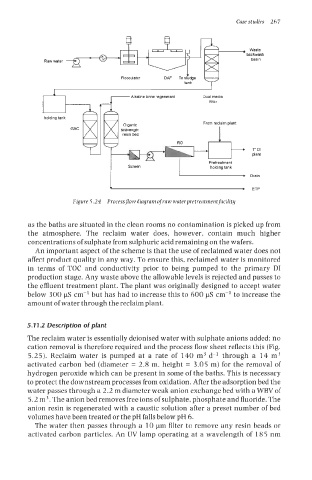

Figure 5.24 Processflow diagram ofraw waterpretreatmentfacility

as the baths are situated in the clean rooms no contamination is picked up from

the atmosphere. The reclaim water does, however, contain much higher

concentrations of sulphate from sulphuric acid remaining on the wafers.

An important aspect of the scheme is that the use of reclaimed water does not

affect product quality in any way. To ensure this, reclaimed water is monitored

in terms of TOC and conductivity prior to being pumped to the primary DI

production stage. Any waste above the allowable levels is rejected and passes to

the effluent treatment plant. The plant was originally designed to accept water

below 300 pS cm-l but has had to increase this to 600 pS cm-l to increase the

amount of water through the reclaim plant.

5.11.2 Description of plant

The reclaim water is essentially deionised water with sulphate anions added: no

cation removal is therefore required and the process flow sheet reflects this (Fig.

5.25). Reclaim water is pumped at a rate of 140 m3 d-l through a 14 m3

activated carbon bed (diameter = 2.8 m, height = 3.05 m) for the removal of

hydrogen peroxide which can be present in some of the baths. This is necessary

to protect the downstream processes from oxidation. After the adsorption bed the

water passes through a 2.2 m diameter weak anion exchange bed with a WBV of

5.2 m3. The anion bed removes free ions of sulphate, phosphate and fluoride. The

anion resin is regenerated with a caustic solution after a preset number of bed

volumes have been treated or the pH falls below pH 6.

The water then passes through a 10 pm filter to remove any resin beads or

activated carbon particles. An UV lamp operating at a wavelength of 18 5 nm