Page 285 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 285

254 Membrnnesfor Induslrial Wastewater Recovery and Re-use

0.001 across all the consented wavelengths. Heavy metal removal was also very

good with chromium concentration reducing from 0.75 to less than 0.02 mg 1-l.

The installation of the plant was required by changes to discharge consents

but the ability to recycle water within the plant provided a number of economic

advantages to ensure the scheme became financially viable. Major savings were

achieved in the cost of softened mains water (by 95%) and the reduction of

effluent charges. A less obvious saving was made by the reduction in heat

demand achieved by recycling the previously heated water within the process.

The capital cost of the schemes was €275 000 ('5448 800) in 1998 and the

annual net saving on the reuse plant was €142 635 (5232 780) resulting in a

payback time of 1.9 years (Table 5.10). The company ceased production in

March 2001 at which point the quarterly effluent bill had reduced from €12 481

($1 7 723), prior to the reuse plant, down to €640 ($908). Overall the decision to

install the plant resulted in a profit to the company of €182 067 ($258 535) over

its operational life.

5.8 N food plant wastewater treatment and recycling plant (Japan)

5.8.7 Background

Yokosuka city, situated in the Kanagawa Prefecture has no nearby rivers and

as such water is supplied from water treatment plants situated on the Sagami

river a distance of 30 km away. N company is a producer of frozen foods (such

as Chinese and Japanese dishes) and is situated within Yokosuka city and so

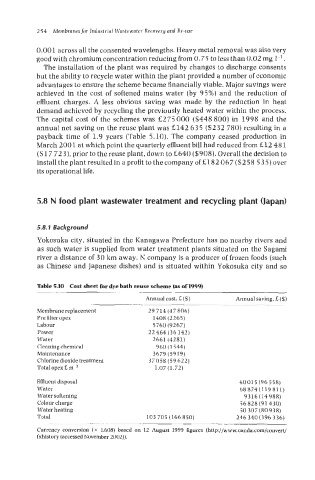

Table 5.10 Cost sheet for dye bath reuse scheme (as of 1999)

Annual cost, f. (S) Annual saving, € ($)

Membrane replacement 29 714 (47 806)

Prefilter opex 1408 (2265)

Labour 5760 (9267)

Power 22 464 (36 142)

Water 2661 (4281)

Cleaning chemical 960 (1 544)

Maintenance 3679 (5919)

Chlorine dioxide treatment 37 058 (59 622)

Total opex E mM3 1.07(1.72)

Effluent disposal 60015 (96 558)

Water 68 874(119 811)

Water softening 9316 (14988)

Colour charge 56 828 (91 430)

Water heating 50 307 (80938)

Total 103 705 (166 850) 246 340 (396 336)

~

Currency conversion (x 1.608) based on 12 August 1999 figures (http://www.oanda.cOm/convert/

fxhistory (accessed November 2002)).