Page 205 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 205

Chapter 1.12

Mitsubishi Motors Corporation - Mitsubishi Electric

Corporation

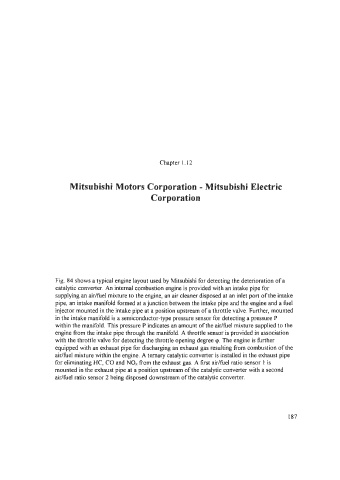

Fig. 84 shows a typical engine layout used by Mitsubishi for detecting the deterioration of a

catalytic converter. An internal combustion engine is provided with an intake pipe for

supplying an aidfie1 mixture to the engine, an air cleaner disposed at an inlet port of the intake

pipe, an intake manifold formed at a junction between the intake pipe and the engine and a fuel

injector mounted in the intake pipe at a position upstream of a throttle valve. Further, mounted

in the intake manifold is a semiconductor-type pressure sensor for detecting a pressure P

within the manifold. This pressure P indicates an amount of the aidfuel mixture supplied to the

engine fiom the intake pipe through the manifold. A throttle sensor is provided in association

with the throttle valve for detecting the throttle opening degree cp. The engine is firther

equipped with an exhaust pipe for discharging an exhaust gas resulting fiom combustion of the

aidfie1 mixture within the engine. A ternary catalytic converter is installed in the exhaust pipe

for eliminating HC, CO and NO, from the exhaust gas. A first aidfie1 ratio sensor 1 is

mounted in the exhaust pipe at a position upstream of the catalytic converter with a second

aidfie1 ratio sensor 2 being disposed downstream of the catalytic converter.

187