Page 129 -

P. 129

3.4 Applications of Optical Tweezers 119

Light guide

CCD camera

Mirror G.M.

Filter Axis

Half mirror Filter Eyeplece

Lens alignment

Expander plates

G.M.

G.M.

Dichroic mirror

Movement

Half mirror Iris

Mirror ND filter G.M.

Mirror Movement Dichroic mirror

Quater-wave plate Expander Pinhole

Lens Objective lens

Ar laser for assembly Mirror Specimen

(l = 514.5 nm) plane

Mirror

Objective lens

Filter

Quater-wave plate Fillter

CCD camera

YAG laser for adhesion (l = 355 nm)

(l = 355 nm)

Mirror

Iris

Illuminator

Filter

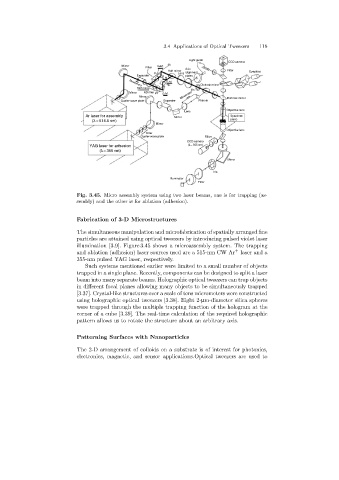

Fig. 3.45. Micro assembly system using two laser beams, one is for trapping (as-

sembly)and the other is for ablation (adhesion).

Fabrication of 3-D Microstructures

The simultaneous manipulation and microfabrication of spatially arranged fine

particles are attained usingoptical tweezers by introducingpulsed violet laser

illumination [3.9]. Figure 3.45 shows a microassembly system. The trapping

+

and ablation (adhesion) laser sources used are a 515-nm CW Ar laser and a

355-nm pulsed YAG laser, respectively.

Such systems mentioned earlier were limited to a small number of objects

trapped in a single plane. Recently, components can be designed to split a laser

beam into many separate beams. Holographic optical tweezers can trap objects

in different focal planes allowingmany objects to be simultaneously trapped

[3.37]. Crystal-like structures over a scale of tens micrometers were constructed

using holographic optical tweezers [3.38]. Eight 2-µm-diameter silica spheres

were trapped through the multiple trapping function of the hologram at the

corner of a cube [3.39]. The real-time calculation of the required holographic

pattern allows us to rotate the structure about an arbitrary axis.

Patterning Surfaces with Nanoparticles

The 2-D arrangement of colloids on a substrate is of interest for photonics,

electronics, magnetic, and sensor applications.Optical tweezers are used to