Page 19 -

P. 19

8 1 From Optical MEMS to Micromechanical Photonics

2R

Lens

f

2romin x

w

v

L

Liquid

y

photopolymer

Solid

z

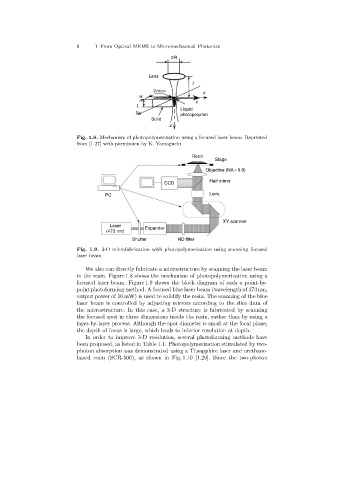

Fig. 1.8. Mechanism of photopolymerization using a focused laser beam. Reprinted

from [1.27] with permission by K. Yamaguchi

Resin

Stage

Objective (NA = 0.8)

Half mirror

CCD

PC Lens

XY scanner

Laser

(473 nm) Expander

Shutter ND filter

Fig. 1.9. 3-D microfabrication with photopolymerization using scanning focused

laser beam

We also can directly fabricate a microstructure by scanningthe laser beam

in the resin. Figure 1.8 shows the mechanism of photopolymerization using a

focused laser beam. Figure 1.9 shows the block diagram of such a point-by-

point photoformingmethod. A focused blue laser beam (wavelength of 473 nm,

output power of 10 mW) is used to solidify the resin. The scanningof the blue

laser beam is controlled by adjustingmirrors accordingto the slice data of

the microstructure. In this case, a 3-D structure is fabricated by scanning

the focused spot in three dimensions inside the resin, rather than by usinga

layer-by-layer process. Although the spot diameter is small at the focal plane,

the depth of focus is large, which leads to inferior resolution at depth.

In order to improve 3-D resolution, several photoformingmethods have

been proposed, as listed in Table 1.1. Photopolymerization stimulated by two-

photon absorption was demonstrated usinga Ti:sapphire laser and urethane-

based resin (SCR-500), as shown in Fig. 1.10 [1.29]. Since the two-photon